Call: 07971891537( PIN:797)

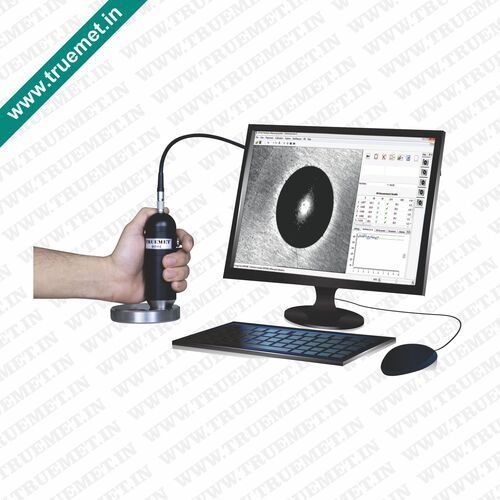

Brinell Impression Measurement System

MOQ : 1 Unit

Brinell Impression Measurement System Specification

- Power Supply

- 120-280 V

- Voltage

- 120-280 Volt (v)

- Response Time

- <1 sec

- Application

- Industrial

- Temperature

- 10°C to 40°C

- Color

- White & Blue

- Mounting Type

- Bench-top

- Display Type

- Digital LCD

- Number of Specimens

- Single or multiple

- Features

- High precision, Automatic calculation, Data storage

- Operating Voltage

- 120-280 V

- Hardness

- Up to 700 HBW

- Resolution

- 0.001 mm

- Humidity

- 10% ~ 90% RH (non-condensing)

- Max Height

- 300 mm

- Frequency

- 50-60 Hz

- Automation Grade

- Automatic

- Accuracy

- ±0.01 mm

- Measuring Range

- 1-6 mm

- Product Type

- Brinell Impression Measurement System

- Port Size

- Standard USB / RS232

- Test Range

- 1 mm to 6 mm (diameter of impression)

- Interface Type

- USB / RS232

- Specimen Size

- Up to 300 mm (height)

- Usage

- Hardness measurement

- Capacity

- Up to 1000 readings stored

- Machine Weight

- 2-25 Kilograms (kg)

- Test Speed

- Up to 5 impressions per minute

- Test Width

- 150 mm

- Test Stroke

- 120 mm

- Control Mode

- Automatic

Brinell Impression Measurement System Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- Week

- Main Domestic Market

- All India

About Brinell Impression Measurement System

Brinell Impression measurement System

It is found that measuring Brinell Indentations can result in measurement errors between operators. This B.I.M.S can virtually eliminate operator influence on test results.

Specifications

The range of measurement is from 1min to 6mm of diameter with resolution of 0.01 mm.

Application

- To measure Brinell Hardness directly on machine where presently Brinell Microscope is used. This avoids eye straining of operator on production testing. In addition it gives far better repeated accuracy. High- Low limits selection enables operator easy acceptance rejection of components.

- Easy to transport anywhere and handy for use with easy set up.

- One hand held unit containing CCD Camera, Optics and illumination system with connecting cable.

- PCI Video capture card with driver software.

- Brinell image Analysis System software

4. PC and Windows 98/98 SE operating system is to be procured by customer.

State-of-the-Art Imaging for Precision

Equipped with a 20x optical magnification camera and high-resolution CMOS image sensor, this system captures fine Brinell impressions with unmatched clarity. The adjustable LED lighting ensures optimal visibility, while digital LCD readouts and advanced image processing algorithms guarantee accurate measurement across a 1-6 mm diameter range. This high degree of precision is essential for consistent hardness testing in demanding workshops and laboratories.

Seamless Integration and Workflow

Supporting both automatic and manual calibration, the system runs on Windows 7, 10, and 11 platforms, making it easy to integrate into existing industrial environments. Data management is streamlined with storage for up to 1,000 readings and output options including CSV files, USB, printers, and standard RS232 ports. It handles single or multiple specimens and ensures secure, efficient workflow for operators and quality control teams alike.

FAQs of Brinell Impression Measurement System:

Q: How does the Brinell Impression Measurement System determine hardness?

A: This system uses an image processing algorithm with a high-resolution CMOS camera to accurately measure the diameter of Brinell impressions on specimens. It then calculates the Brinell Hardness Number automatically, ensuring high precision (0.01 mm accuracy) and rapid results.Q: What types of specimens can the system accommodate, and what is the size range?

A: The device can test single or multiple industrial metal specimens, handling heights up to 300 mm. It measures Brinell impressions with diameters between 1 mm and 6 mm, making it versatile for various component types.Q: When should the systems calibration be performed?

A: Calibration should be carried out during installation, after major maintenance, or when measurement consistency needs verification. The system supports both automatic and manual calibration modes for convenience and precision.Q: Where can the Brinell Measurement System be installed for effective use?

A: Designed as a bench-top unit, it is ideal for industrial labs, manufacturing plants, or quality control departments. Its rugged construction and wide voltage range (120-280 V) allow reliable operation in diverse industrial settings.Q: What is the process for taking and storing measurements?

A: After placing the specimen, the system automatically captures the impression image, processes it, and calculates the hardness. Up to 1,000 readings can be stored, and data can be exported in CSV format, printed, or transferred via USB/RS232.Q: How does using this system benefit industrial users?

A: It delivers fast, precise, and repeatable Brinell hardness measurements, reducing manual effort and minimizing human error. Automatic calculation, data storage, and multiple output options enhance productivity and streamline reporting for industrial and quality control applications.

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry