Computer Controlled Electro Mechanical Universal Testing Machine (Single Ball Screw)

Computer Controlled Electro Mechanical Universal Testing Machine (Single Ball Screw) Specification

- Temperature

- 10°C - 35°C

- Operating Voltage

- 220V AC

- Max Height

- 1315 mm

- Automation Grade

- Automatic

- Features

- Data Logging, Overload Protection, Emergency Stop, Graphical Results

- Mounting Type

- Floor Standing

- Test Range

- Full capacity

- Frequency

- 50 Hz

- Application

- Tensile, Compression, Bending, Shear and other mechanical tests

- Equipment Type

- Universal Testing Machine (Single Ball Screw)

- Port Size

- Standard

- Response Time

- Realtime sampling

- Power Supply

- 220V AC, 50Hz

- Specimen Size

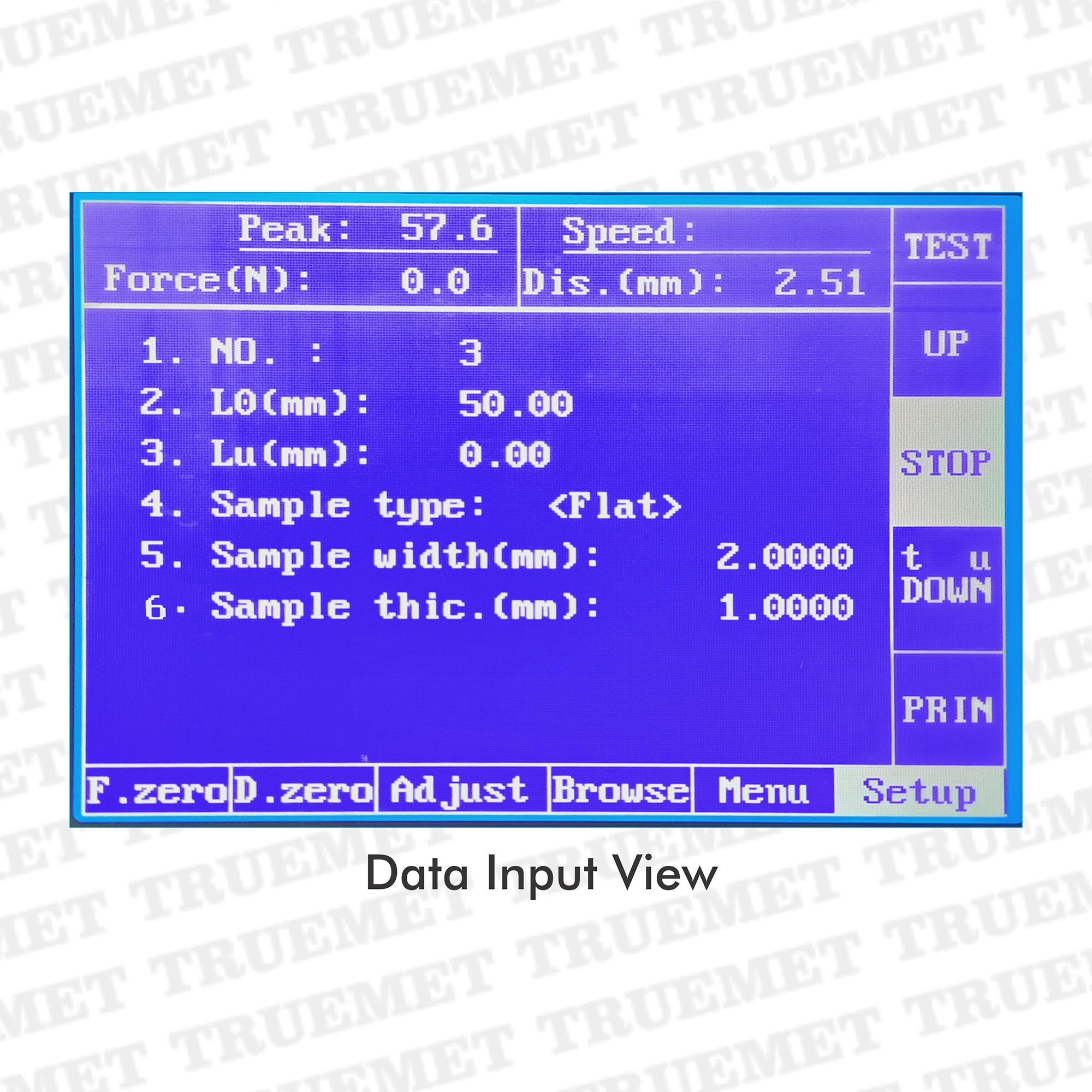

- Customizable as per grips and application

- Display Type

- Digital / Computer Display

- Number of Specimens

- Single specimen

- Humidity

- 20% - 80% RH (non-condensing)

- Accuracy

- ±1% of indicated value

- Dimension (L*W*H)

- 425x400x1315 Millimeter (mm)

- Resolution

- 0.001 mm / 0.01 N

- Interface Type

- USB / RS232

- Measuring Range

- 1% to 100% of capacity

- Usage

- Material Testing in Laboratories/Industries

- Capacity

- 5 kN, 10 kN, 20 kN, 50 kN (choose variant)

- Machine Weight

- 90 Kilograms (kg)

- Test Speed

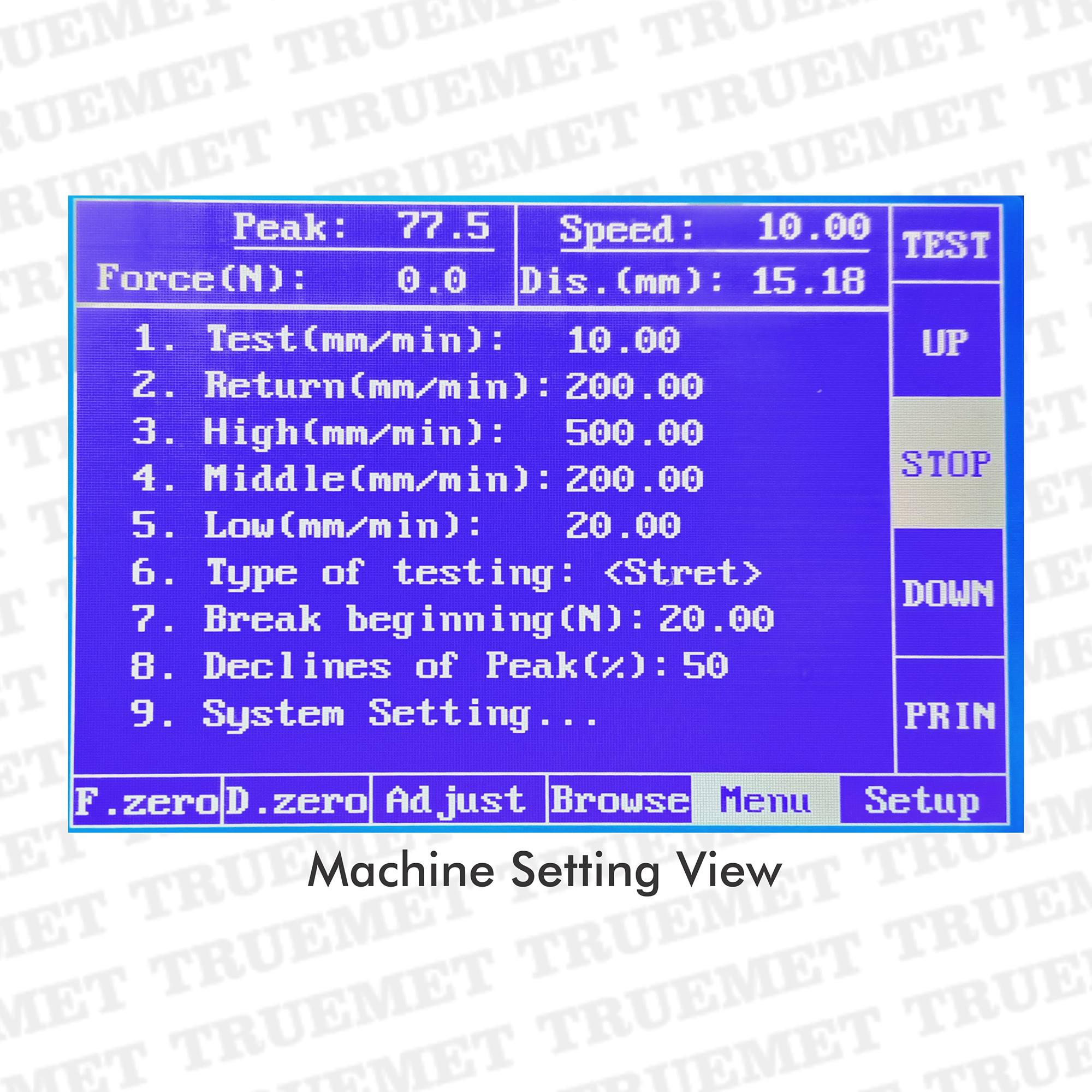

- 0.1 - 500 mm/min adjustable

- Test Width

- 400 mm

- Test Stroke

- 600 mm

- Control Mode

- Computer Controlled / Electro-Mechanical

Computer Controlled Electro Mechanical Universal Testing Machine (Single Ball Screw) Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Number Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Computer Controlled Electro Mechanical Universal Testing Machine (Single Ball Screw)

Features

Load is indicated with resolution of 1/20000 of machine capacity for the entire measuring range.

Elongation is indicated with the resolution of 0.01 mm.

Tare load and reset elongation facilities available.

Special data acquisition card with software compatible with Windows 7, Window 8 & Windows 10 operating system.

Software can run a variety of mechanical test, recall data from previous test and prepare test report.

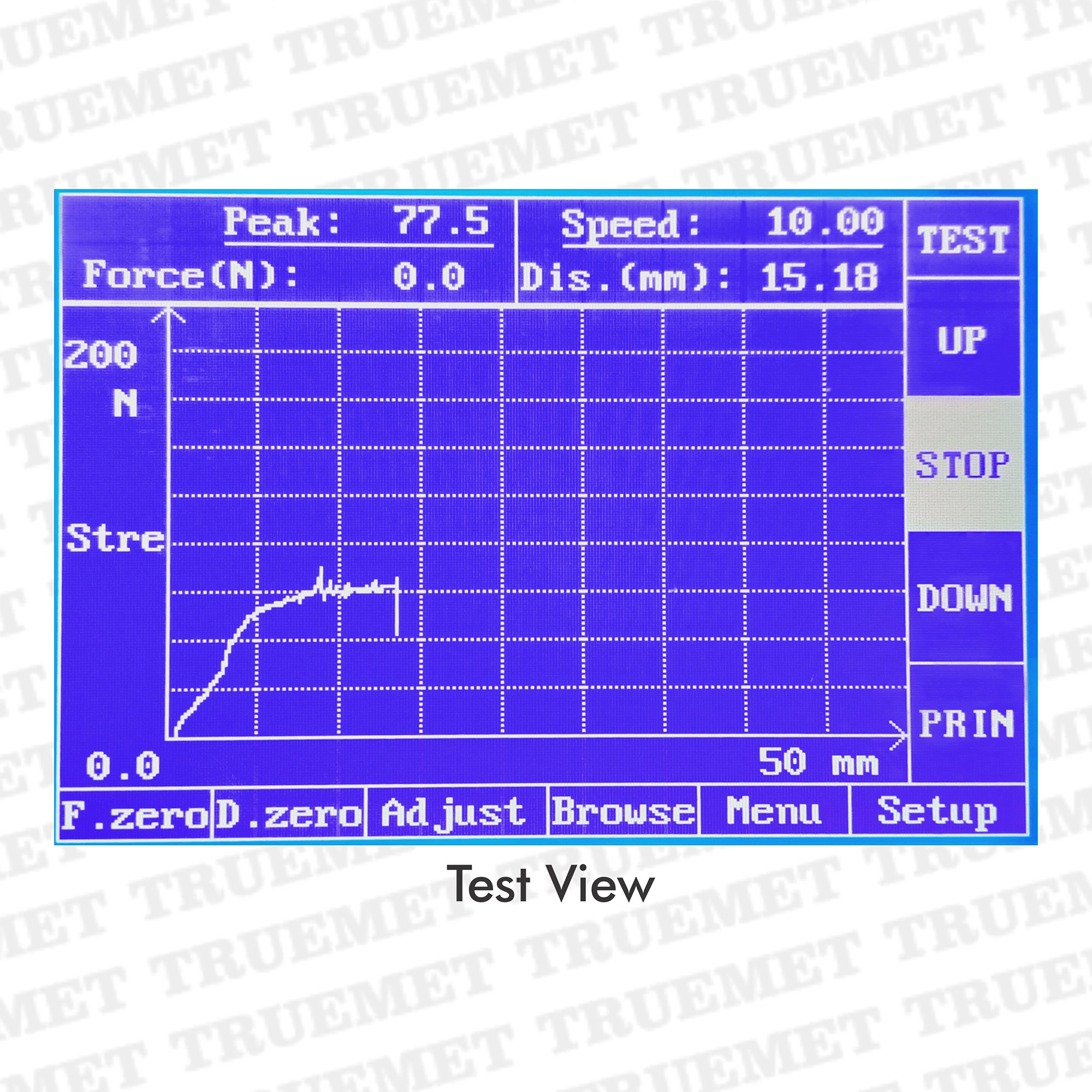

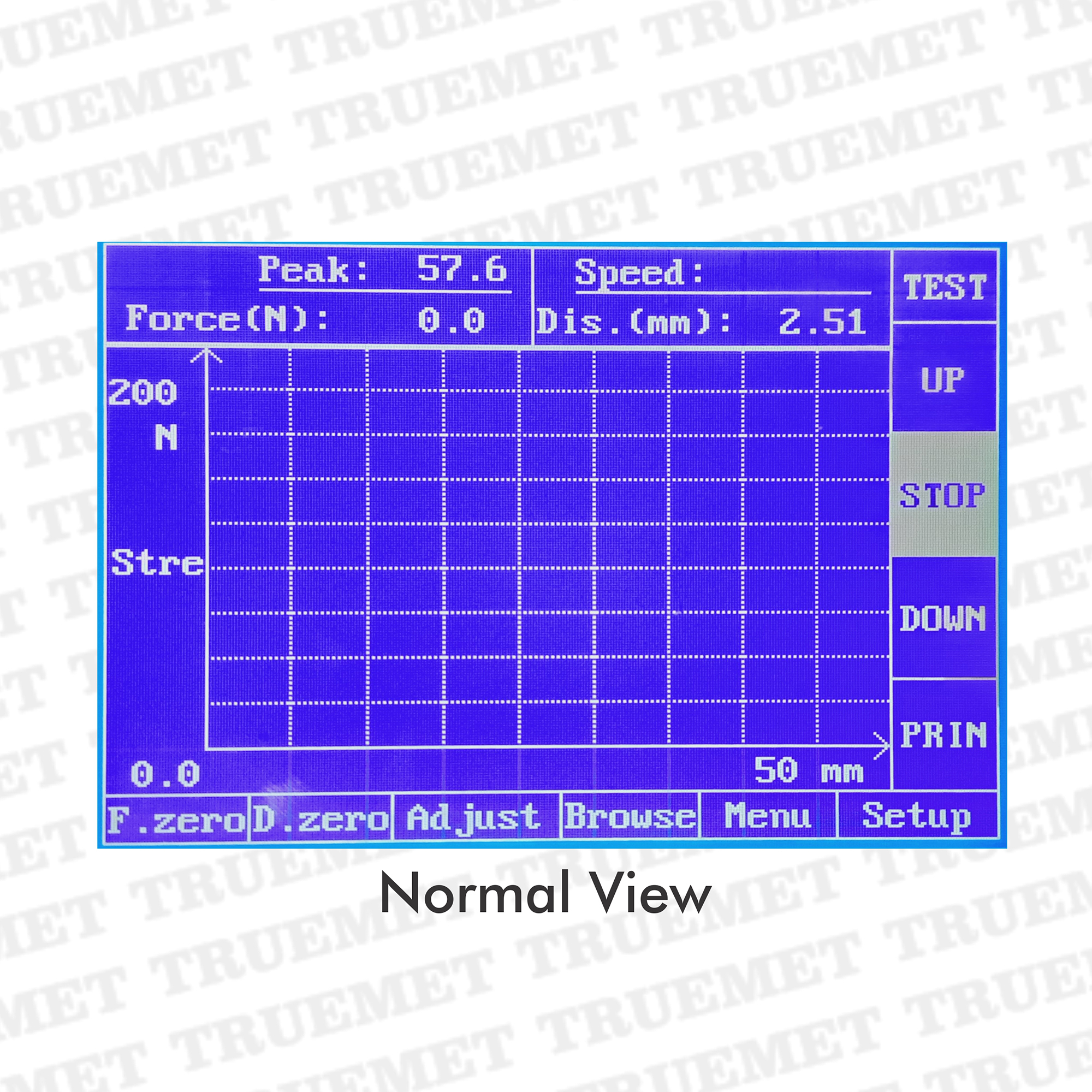

User can choose different option for online graph, eg. Load vs Displacement, Load vs Extension, Stress vs Strain, Load vs Time etc.

Menu driven software for easy use.

Storage and retrieval of test parameters.

The load and crosshead travel value will be displayed continuously during the test with the online graph, if extensometer is used during the testing then load, elongation and extension value will be display with live graph.

Zooming and magnification of required portion of graph is available.

Point tracing facilities are available as added feature.

Different units can be selected for load in KN and Kg.

Tare load and reset elongation facility.

Robust Construction for Precise Testing

Built with a heavy-duty, rigid steel frame, this Universal Testing Machine integrates a precision ball screw drive and servo motor for highly accurate and consistent crosshead movement. Its floor-standing design, combined with overtravel limit switches and an emergency stop function, enables safe and dependable use in laboratories or industrial environments.

Versatile Material Testing Applications

Suited for a variety of material testssuch as tensile, compression, bending, and shearthe system accommodates single specimens of customizable size. With a test width of 400 mm and stroke of 600 mm, users can select from a range of interchangeable grip types. The machine supports a measuring range from 1% to 100% of capacity and maintains 1% accuracy.

Advanced Software and Data Reporting

The included comprehensive software enables detailed analysis, report generation, and complies with ASTM, ISO, and BIS standards. Users benefit from real-time sampling, graphical outputs (Load vs Displacement, Stress vs Strain), and flexible data logging via both USB and RS232 interfaces, streamlining workflow and result management.

FAQs of Computer Controlled Electro Mechanical Universal Testing Machine (Single Ball Screw):

Q: How does the Computer Controlled Electro Mechanical Universal Testing Machine operate?

A: The machine utilizes a precision ball screw drive, controlled by a servo motor, to move the crosshead smoothly and accurately as per preset parameters. Operations and adjustments are made via computer software, which manages test procedures and provides real-time data acquisition.Q: What types of tests can be performed with this Universal Testing Machine?

A: It is equipped to perform tensile, compression, bending, and shear tests, making it ideal for a broad range of material testing applications in both laboratory and industrial environments.Q: When should I use the interchangeable grips, and what options are available?

A: Interchangeable grips should be selected depending on the specimens characteristics and the specific test being performed. Available options include wedge, pneumatic, and customized grips to accommodate different shapes and sizes of test specimens.Q: Where can this testing machine be installed and used effectively?

A: Designed as a floor-standing unit, the machine is suitable for laboratories, quality control rooms, and industrial testing facilities. Its 1315 mm height and 90 kg weight offer flexible placement within standard working environments.Q: What is the process for conducting material tests with this equipment?

A: Place your specimen between the specialized grips, select the desired test procedure via the integrated software, and initiate the test. The machine records force and displacement data in real-time, displaying graphical results and analysis upon completion.Q: How does the machine ensure operator safety during testing?

A: Safety features include overtravel limit switches, an emergency stop button, and overload protection. These systems prevent damage to the machine and ensure user safety during operation.Q: What are the main benefits of using this Universal Testing Machine?

A: Key advantages include high-precision measurements, standardized report generation, compliance with international test norms, customizable test parameters, robust safety protocols, and user-friendly controlsenabling reliable and efficient material property evaluation.

More Products in Universal Testing Machine Category

Electro Mechanical Servo Control Universal Testing Machine (CEDN Series)

Minimum Order Quantity : 1 Number

Voltage : AC220 Volt (v)

Machine Weight : 420 to 680 Kilograms (kg)

Power : AC220 Volt (v)

Application : Tensile, Compression, Bending, Shear Testing of Metals, Alloys, Polymers & More

Test Width : 420 mm

Analogue Universal Testing Machine

Minimum Order Quantity : 1 Unit

Voltage : 120280 Volt (v)

Machine Weight : 5100 Kilograms (kg)

Application : Industrial

Servo Control Universal Testing Machine

Minimum Order Quantity : 1 Unit

Voltage : 120440 Volt (v)

Machine Weight : 1002000 Kilograms (kg)

Application : Industrial

Electro Mechanical Universal Testing Machine

Minimum Order Quantity : 1 Bottle

Voltage : AC220 Volt (v)

Machine Weight : 160 to 800 Kilograms (kg)

Power : AC220V±10%, 50Hz Volt (v)

Test Width : 400 to 550 Millimeter (mm)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry