Electro Mechanical Servo Control Universal Testing Machine (CEDN Series)

Electro Mechanical Servo Control Universal Testing Machine (CEDN Series) Specification

- Port Size

- Standard

- Power Supply

- AC 220V, 50/60Hz

- Automation Grade

- Automatic

- Max Height

- 1750 mm (approx.)

- Power

- AC220 Volt (v)

- Temperature

- 10°C – 40°C

- Accuracy

- ±1% of Indicated Value

- Application

- Tensile, Compression, Bending, Shear Testing of Metals, Alloys, Polymers & More

- Number of Specimens

- 1

- Measuring Range

- 2% – 100% of Full Scale

- Frequency

- 50/60 Hz

- Specimen Size

- Up to 420 mm width, up to 800 mm stroke

- Humidity

- 10% – 90% RH (Non-Condensing)

- Equipment Type

- Universal Testing Machine

- Resolution

- 0.01 mm

- Response Time

- Instantaneous (<1 sec)

- Interface Type

- USB/RS232/PC

- Voltage

- AC220 Volt (v)

- Operating Voltage

- AC220V

- Display Type

- Digital Display/ PC Interface

- Features

- User Friendly Interface, Data Logging, Overload Protection, Emergency Stop

- Mounting Type

- Floor Standing

- Test Range

- 2% – 100% Capacity

- Usage

- Laboratory, Research, Industrial QC

- Capacity

- 10 kN, 20 kN, 50 kN, 100 kN (varies by model)

- Machine Weight

- 420 to 680 Kilograms (kg)

- Test Speed

- 0.05 – 500 mm/min

- Test Width

- 420 mm

- Test Stroke

- 800 mm

- Control Mode

- Electro-Mechanical Servo Control

Electro Mechanical Servo Control Universal Testing Machine (CEDN Series) Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Number Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

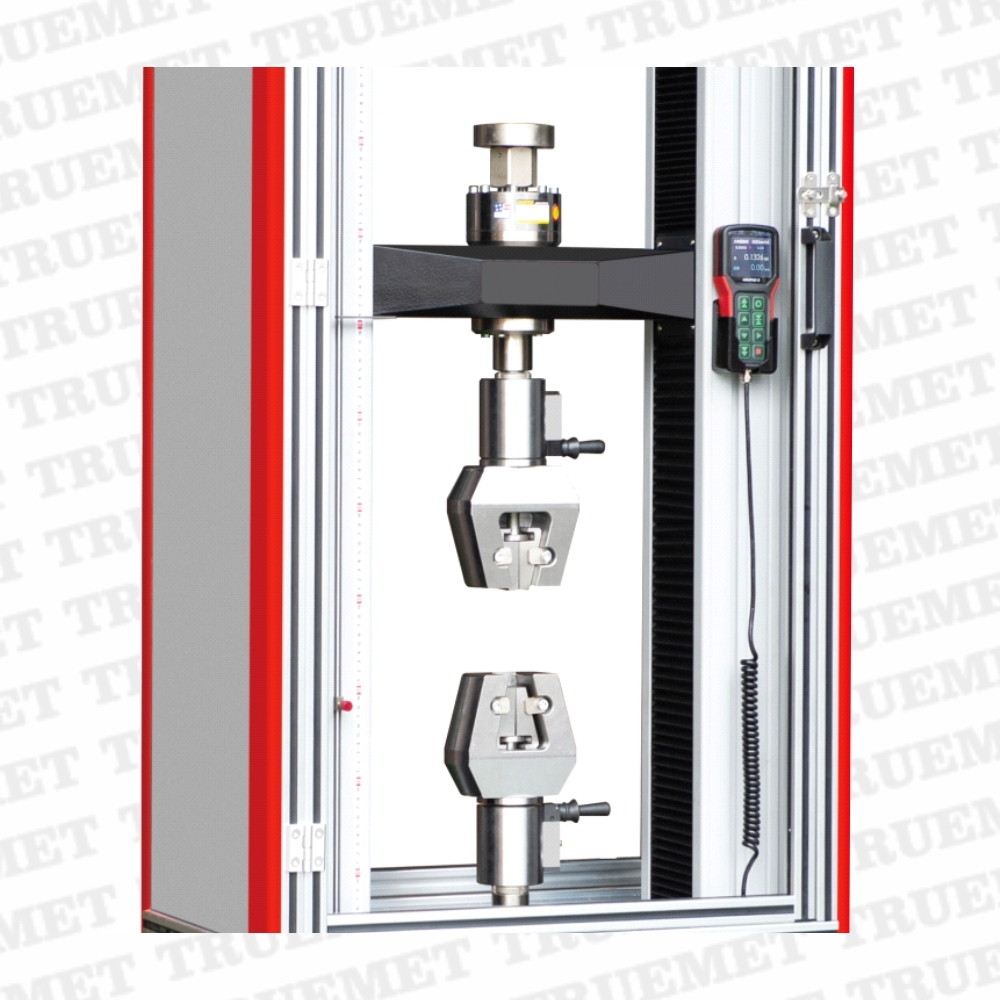

About Electro Mechanical Servo Control Universal Testing Machine (CEDN Series)

Features

4 Column 2 ball screw driven & double spaces.

Testing speed available from 0.01mm/min to 500mm/min.

Panasonic AC servo motor and AC drive.

Three test speed control module (Displacement control, Load control and Extension control module).

Machine can be configured with four different load cells. Users can switch between these load cells as per requirements.

Machine can be configured with eight different extensometer sensors. Users can switch between these sensors as per requirements.

Advanced Control and Measurement

The CEDN Series incorporates state-of-the-art electro-mechanical servo control for smooth, precise movement and instantaneous response. An encoder-based displacement system and high-precision strain gauge load cell ensure accuracy and reliability, crucial for a wide spectrum of materials testing applications. The digital display and PC interface allow seamless observation and control of tests.

Versatility in Applications

With a test width of 420 mm and a stroke of up to 800 mm, this universal testing machine accommodates a single specimen across a range of industries. It is suitable for research, routine laboratory assessments, and industrial QC, enabling tensile, compression, bending, and shear testing of metals, alloys, and polymers, among other materials.

Comprehensive Safety and User Experience

This model integrates essential safety features like overload and over-travel protection, along with an emergency stop for operator security. Its durable heavy-duty steel frame ensures stability, while a user-friendly Windows-based software interface supports detailed data logging, analysis, and test reporting to streamline workflow and enhance usability.

FAQs of Electro Mechanical Servo Control Universal Testing Machine (CEDN Series):

Q: How does the Electro Mechanical Servo Control Universal Testing Machine (CEDN Series) ensure testing accuracy?

A: The machine features a high-precision strain gauge load cell and an encoder-based displacement measurement system, ensuring an accuracy of 1% of the indicated value. This enables reliable and repeatable results across various test types, such as tensile, compression, bending, and shear.Q: What is the process for conducting a test using this equipment?

A: To conduct a test, mount the specimen (up to 420 mm width, 800 mm stroke) on the machine, select the appropriate test parameters using the Windows-based software, and initiate the test. The servo-controlled system manages movement, while instantaneous response and digital data logging streamline result analysis and reporting.Q: When should I utilize the overload and emergency stop features?

A: Both the overload and emergency stop functions should be engaged if the machine exceeds its load limits or if an unsafe condition arises during operation. These safety mechanisms help prevent equipment damage and enhance operator safety during testing procedures.Q: Where can this universal testing machine be installed and used?

A: This floor-standing unit is designed for laboratories, research institutions, and industrial quality control rooms. Its robust frame and dimensions (approx. 1000 600 1750 mm) make it suitable for a wide range of professional settings where precise materials testing is required.Q: What benefits does the Windows-based analysis software offer?

A: The integrated, user-friendly software supports intuitive control, automatic data logging, and comprehensive analysis/reporting features. This enhances efficiency, streamlines test management, and facilitates detailed documentation for research and quality assurance purposes.Q: How is data transferred or exported from the machine?

A: Data can be transferred or exported via multiple interface options, including USB and RS232 connections to a PC. This allows for seamless integration with laboratory information systems and enables easy sharing and archiving of test results.

More Products in Universal Testing Machine Category

Computer Control Servo Hydraulic Universal Testing Machine (SCH Series)

Minimum Order Quantity : 1 Number

Machine Weight : 1800 to 1950 Kilograms (kg)

Application : Tensile, Compression, Bending, Shear Testing of Metals and Nonmetals

Voltage : AC 380 Volt (v)

Test Speed : 0.01—300 mm/min

Computer Controlled Electro Mechanical Universal Testing Machine (Single Ball Screw)

Minimum Order Quantity : 1 Number

Machine Weight : 90 Kilograms (kg)

Application : Tensile, Compression, Bending, Shear and other mechanical tests

Test Speed : 0.1 500 mm/min adjustable

Computerized Universal Testing Machine

Minimum Order Quantity : 1 Unit

Machine Weight : 15100 Kilograms (kg)

Application : Industrial

Voltage : 220280 Volt (v)

Product Type : Universal Testing Machine

Analogue Universal Testing Machine

Minimum Order Quantity : 1 Unit

Machine Weight : 5100 Kilograms (kg)

Application : Industrial

Voltage : 120280 Volt (v)

Product Type : Analogue Universal Testing Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry