Load Cell Based Touch Screen Digital Brinell Hardness Tester

Load Cell Based Touch Screen Digital Brinell Hardness Tester Specification

- Response Time

- Instantaneous (Touch Input)

- Hardness

- Brinell

- Equipment Type

- Load Cell Based Brinell Hardness Tester

- Measuring Range

- 8-650 HBW

- Specimen Size

- Up to 215 mm width

- Frequency

- 50 Hz

- Accuracy

- ± 0.5% of indicated value

- Temperature

- 10°C to 35°C

- Display Type

- 7 TFT Touch Screen

- Number of Specimens

- Single Specimen

- Features

- Automatic Load Application, Data Storage, Report Generation, User Friendly Interface

- Humidity

- ≤ 65% RH

- Interface Type

- USB / Ethernet

- Test Range

- 8-650HBW

- Application

- Determination of Brinell Hardness of Metals

- Resolution

- 0.1 HBW

- Max Height

- 240 mm

- Operating Voltage

- 220 V

- Automation Grade

- Fully Automatic

- Mounting Type

- Bench Top

- Port Size

- Standard USB / LAN

- Power Supply

- 220 V AC ±10%, 50 Hz

- Usage

- Laboratory, Industrial

- Capacity

- 3000 kgf (Max)

- Machine Weight

- 130 Kilograms (kg)

- Test Speed

- 0.15 mm/sec

- Test Width

- 215 mm

- Test Stroke

- 175 mm

- Control Mode

- Touch Screen Digital

Load Cell Based Touch Screen Digital Brinell Hardness Tester Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Load Cell Based Touch Screen Digital Brinell Hardness Tester

FEATURES

Load Cell Based Touch Screen Digital Brinell Hardness Tester.

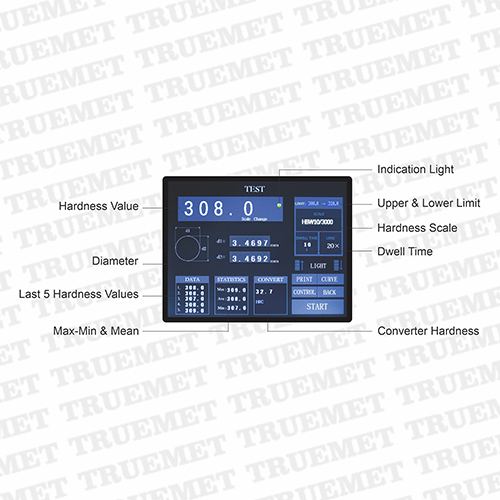

The hardness value can be displayed directly and no need to enter the length of the diagonal.

Automatic switching of indenter and objective lenses.

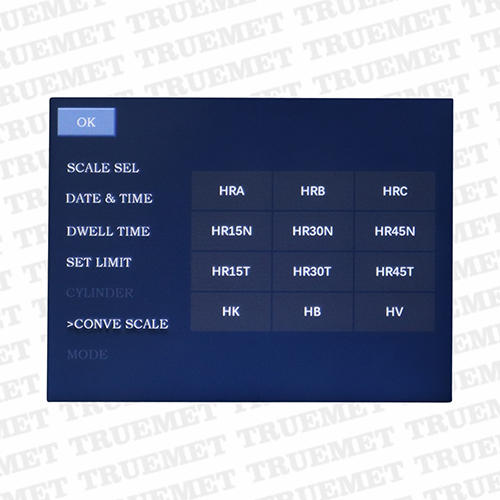

Load/Scale selection through touch panel.

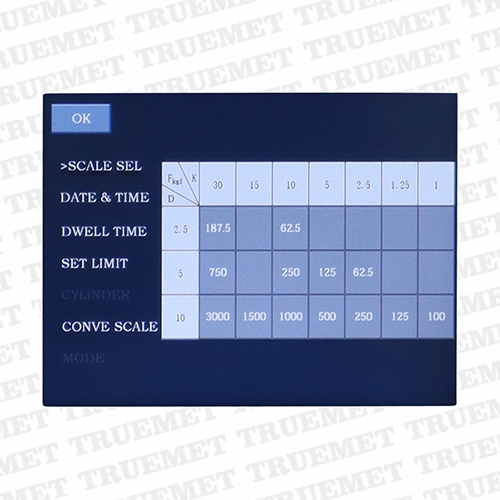

Wide test force from 62.5, 100, 125, 187.5, 250, 500, 750, 1000, 1500 & 3000 kgf.

Automatic testing (Loading, Dwell, Unloading), no need to apply initial test force.

User can measure the diameter of impression by 10X Digital Eyepiece.

Advanced Touch Screen Control

This tester features a 7-inch TFT touch screen for easy operation and navigation. The instantaneous response to touch input streamlines the testing process, allowing users to select test parameters, view results, and manage data efficiently. Its user-friendly interface supports multiple languages for convenient accessibility.

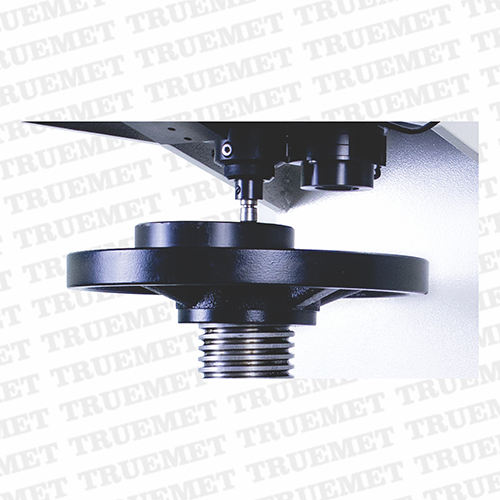

Precision Optical Measurement

Integrated high-resolution digital camera technology ensures accurate and repeatable optical measurements of the indentation. Coupled with load cell-based force application and selectable dwell times, the tester delivers reliable Brinell hardness values for a wide range of metals.

Efficient Data Management

Test results can be saved securely within the instruments memory, supporting up to 1000 data records and easy export via USB or Ethernet interfaces. The Windows-based software allows comprehensive data analysis, report generation, and connectivity, promoting streamlined workflow in industrial or lab environments.

FAQs of Load Cell Based Touch Screen Digital Brinell Hardness Tester:

Q: How does the load cell-based automatic force application work in this Brinell Hardness Tester?

A: The tester uses a precision load cell to automatically apply test forces from 187.5 to 3000 kgf, ensuring uniform and repeatable indentation. The process eliminates manual adjustments, enhancing accuracy and reducing operator dependency.Q: What is the procedure for conducting a test with this equipment?

A: Users mount a single specimen (up to 215 mm wide) on the bench top machine, select parameters (force, indenter, dwell time) via the touch screen, and initiate the test. The load cell applies the chosen force, the camera captures indentation images, and data is stored for analysis.Q: When should I consider using this Brinell Hardness Tester?

A: This tester is ideal for laboratories and industrial environments requiring high-accuracy Brinell hardness measurements of metals across the 8650 HBW range, especially where data management, automation, and reliable reporting are critical.Q: Where can I export and analyze test data from the instrument?

A: Test data can be exported via USB or Ethernet for direct transfer to Windows-based data analysis software, allowing comprehensive reporting and record maintenance. It supports secure connectivity for seamless integration into laboratory or industrial data systems.Q: What are the benefits of camera integration in this hardness tester?

A: The high-resolution digital camera provides precise optical measurement of the Brinell indentation, improving measurement accuracy and repeatability. It simplifies result documentation and enables advanced analysis through imaging software.Q: How user-friendly is the interface for various operators?

A: With a multilingual touch screen, automatic load application, and intuitive menu navigation, users of different languages and skill levels can operate the tester efficiently. Instantaneous touch response further improves workflow and ease-of-use.Q: What types of hardness tests and specimen sizes are supported?

A: The tester performs Brinell hardness tests on metal specimens up to 215 mm wide and 240 mm maximum height, supporting 2.5 mm, 5 mm, and 10 mm ball indenters and providing results in the 8650 HBW range.

More Products in Brinell Hardness Tester Category

Touch Screen Brinell Hardness Tester (Weight Type)

Minimum Order Quantity : 1 Number

Machine Weight : 125 Kilograms (kg)

Dimension (L*W*H) : 705X240X830 Millimeter (mm)

Application : Metals Hardness Measurement

Power Supply : AC220V ±50Hz

Automation Grade : SemiAutomatic

Portable Hydraulic Brinell Hardness Tester

Minimum Order Quantity : 1 Number

Machine Weight : 14 Kilograms (kg)

Dimension (L*W*H) : 350mm (Height) x 100mm(Throat depth)

Application : Onsite Brinell Hardness Testing of Metals

Power Supply : Not Required (Manual)

Automation Grade : Manual

Brinell Hardness Tester

Minimum Order Quantity : 1 Unit

Machine Weight : 50150 Kilograms (kg)

Application : Industrial

Load cell based digital Brinell hardness tester.

Minimum Order Quantity : 1 Number

Machine Weight : 120 Kilograms (kg)

Dimension (L*W*H) : 520X210X745 Millimeter (mm)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry