Touch Screen Brinell Hardness Tester (Weight Type)

Touch Screen Brinell Hardness Tester (Weight Type) Specification

- Equipment Type

- Brinell Hardness Tester (Weight Type)

- Response Time

- Fast

- Resolution

- 0.1 HBW

- Specimen Size

- Max Height 705 mm

- Accuracy

- High Precision

- Temperature

- 10°C~35°C

- Application

- Metals Hardness Measurement

- Interface Type

- USB/RS232

- Gas Pressure

- Normal Atmospheric Pressure

- Test Range

- 8-650HBW

- Frequency

- 50 Hz

- Measuring Range

- 8-650 HBW

- Automation Grade

- Semi-Automatic

- Number of Specimens

- Single/Multiple

- Power

- AC220V±50Hz Volt (v)

- Humidity

- ≤85% RH

- Mounting Type

- Tabletop

- Operating Voltage

- AC220V ±50Hz

- Port Size

- Standard Port

- Power Supply

- AC220V ±50Hz

- Features

- Automatic Loading, Touch Operation

- Max Height

- 830 mm

- Hardness

- Brinell

- Display Type

- Touch Screen LCD

- Dimension (L*W*H)

- 705X240X830 Millimeter (mm)

- Usage

- Material Laboratory, Industrial

- Capacity

- High Capacity

- Machine Weight

- 125 Kilograms (kg)

- Test Speed

- Standard

- Test Width

- 240 mm

- Test Stroke

- 830 mm

- Control Mode

- Touch Screen Operation

Touch Screen Brinell Hardness Tester (Weight Type) Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Touch Screen Brinell Hardness Tester (Weight Type)

Features

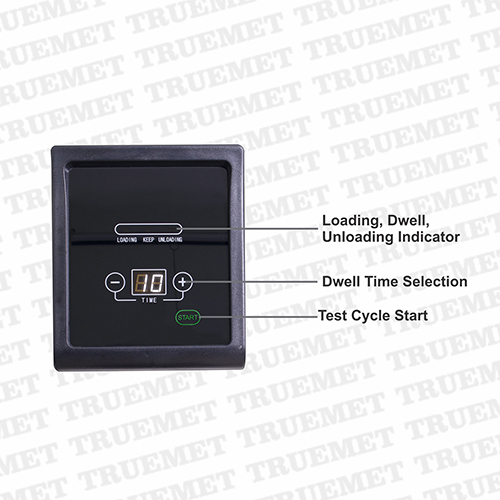

Touch Screen panel for Dwell time selection, and test cycle start.

Wide test force from 187.5, 250, 500, 750, 1000, 1500 & 3000 kgf.

Automatic testing (Loading, Dwell, Unloading), no need to apply preliminary test force.

Precision testing, stable structure and no deformation.

Ability to work in harsh environment.

High Precision and Easy Operation

This Brinell hardness tester combines high precision with convenient usability, thanks to its touch screen interface and automatic measurement features. The integrated control system streamlines routine testing, reduces manual errors, and ensures repeatable results. LED illumination facilitates clearer viewing of indentations, even in low-light conditions.

Flexible Sample Accommodation

Designed to handle both single and multiple specimens, the tester accommodates flat and cylindrical samples up to 705 mm in height. The devices robust cast iron build and high-capacity capabilities make it suitable for a variety of industrial and laboratory applications, offering a test width of 240 mm and stroke of 830 mm.

Advanced Data Management

With internal memory for data storage and USB/RS232 interfaces, users can easily export test results for further analysis or record keeping. Built-in calibration guarantees consistent accuracy, and safety features such as overload protection ensure reliable, secure operation during repeated or extended testing sessions.

FAQs of Touch Screen Brinell Hardness Tester (Weight Type):

Q: How does the Touch Screen Brinell Hardness Tester automatically measure indentation sizes?

A: The tester uses an integrated optical system combined with LED illumination and a touch screen interface to automatically detect and measure indentation sizes, providing fast and precise hardness readings without manual intervention.Q: What types of specimens can be tested with this device?

A: This Brinell hardness tester supports both flat and cylindrical metal specimens, with a maximum specimen height of 705 mm, making it versatile for varied testing requirements in laboratories and industrial environments.Q: When should the built-in calibration function be used?

A: The built-in calibration function should be utilized before testing new batches of specimens, after relocating the device, or periodically to maintain high accuracy and ensure the reliability of measurement results.Q: Where is this hardness tester commonly used?

A: This equipment is widely used in material laboratories, industrial manufacturing, and quality control settings where precise measurement of metal hardness is essential.Q: What is the process for setting the test force?

A: Test force is applied through weight loading. The operator selects the required weights as per the test method, which are then automatically engaged by the integrated control system for each hardness evaluation.Q: How can the data collected by the tester be exported?

A: The device offers USB and RS232 interfaces, enabling users to easily export hardness measurement data for documentation, analysis, or further reporting.Q: What are the benefits of using this Brinell Hardness Tester for industrial applications?

A: Its robust cast iron construction, semi-automatic operation, high precision (0.1 HBW resolution), fast response time, and advanced data management features collectively improve productivity, reliability, and traceability in hardness testing processes.

More Products in Brinell Hardness Tester Category

Portable Hydraulic Brinell Hardness Tester

Minimum Order Quantity : 1 Number

Machine Weight : 14 Kilograms (kg)

Application : Onsite Brinell Hardness Testing of Metals

Dimension (L*W*H) : 350mm (Height) x 100mm(Throat depth)

Display Type : Analogue Dial Indicator

Hardness : Brinell (HBW)

Load Cell Based Touch Screen Digital Brinell Hardness Tester

Minimum Order Quantity : 1 Number

Machine Weight : 130 Kilograms (kg)

Application : Determination of Brinell Hardness of Metals

Display Type : 7 TFT Touch Screen

Hardness : Brinell

Brinell Hardness Tester

Minimum Order Quantity : 1 Unit

Machine Weight : 50150 Kilograms (kg)

Application : Industrial

Load cell based digital Brinell hardness tester.

Minimum Order Quantity : 1 Number

Machine Weight : 120 Kilograms (kg)

Dimension (L*W*H) : 520X210X745 Millimeter (mm)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry