Rockwell Hardness Tester (Weight Type)

Rockwell Hardness Tester (Weight Type) Specification

- Dimension (L*W*H)

- 630x238x466 Millimeter (mm)

- Humidity

- Up to 85% RH

- Number of Specimens

- Single/One at a time

- Operating Voltage

- DC 5V

- Hardness

- Rockwell Scale (HRA, HRB, HRC as applicable)

- Display Type

- Analogue Dial

- Max Height

- 230 mm

- Specimen Size

- Maximum 230 mm height

- Resolution

- 0.1 HRC

- Equipment Type

- Rockwell Hardness Tester (Weight Type)

- Mounting Type

- Bench Top

- Test Range

- 20-70 HRC

- Measuring Range

- 20-70 HRC

- Temperature

- 10°C to 40°C

- Application

- Determination of Rockwell Hardness of Metals and Alloys

- Features

- Manual Loading/Unloading, Rugged Construction, Direct Reading, Stable Base

- Power

- AC240 Volt (v)

- Automation Grade

- Manual

- Power Supply

- AC 240V

- Voltage

- DC 5 Volt (v)

- Frequency

- 50 Hz

- Response Time

- Immediate

- Accuracy

- ±1 HRC

- Usage

- Metallurgical, Industrial, Research

- Capacity

- Maximum test weight 150 kg

- Machine Weight

- 65 Kilograms (kg)

- Test Speed

- As per standard, Manual Operation

- Control Mode

- Manual

Rockwell Hardness Tester (Weight Type) Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Rockwell Hardness Tester (Weight Type)

Features

Motorized Digital Rockwell Hardness Tester.

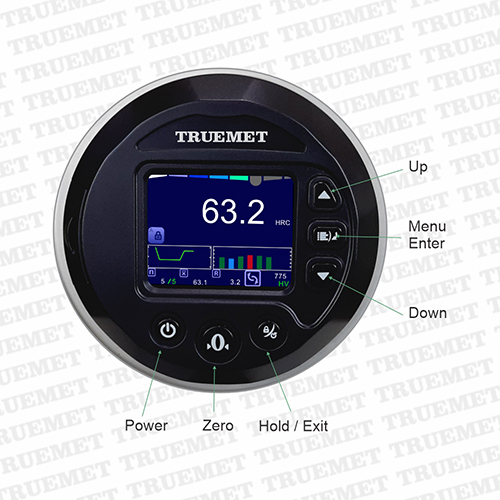

Touch Screen panel for Dwell time selection and test cycle start.

Automatic testing (Loading, Dwell, Unloading) after applying the preliminary test force by hand.

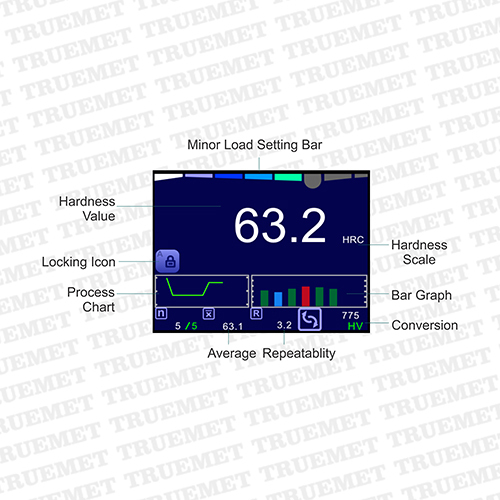

Minor load setting by LCD bar graph.

Tolerance measurement with alarm indication.

Easy to read, large Size 320 x 240 TFT LCD display.

Measurement value can be sent to PC through USB cable (optional).

Memory of 500 measurement values for browsing and output.

Set measurement times (2-9) to have average value and difference to max. and min. value.

Hardness conversion facility available as per ISO-18265 and ASTM-E140 in different scales such as Brinell, Vickers, Knoop, Leeb, Rockwell & Rockwell Superficial.

Automatic power off.

Durable Construction for Reliable Results

Built with cast iron housing and a powder-coated finish, the Rockwell Hardness Tester ensures durability and stability during testing. Its rugged construction and stable base allow for precise testing of metals and alloys, offering consistent performance in demanding industrial, research, and metallurgical settings.

Versatile Testing Capabilities

The tester accommodates specimen heights up to 230 mm and utilizes both diamond cone and steel ball indenters for different Rockwell scale applications. Its test range spans 20-70 HRC with selectable major forces, making it suitable for a variety of metals and alloy hardness measurements. Manual operation gives users full control during each test cycle.

User-Friendly Manual Operation

This Rockwell Hardness Tester operates manually, providing easy loading and unloading, immediate response, and straightforward analogue dial readings. Its direct-reading feature and clear response time streamline the testing process for quality control, research, or production environments.

FAQs of Rockwell Hardness Tester (Weight Type):

Q: How does the Rockwell Hardness Tester (Weight Type) operate?

A: The tester uses a manual operation mode, where an operator places the specimen, applies an initial (preliminary) test force of 10 kgf, followed by a major test forceselectable as 60, 100, or 150 kgf. The resulting indentation is measured via an analogue dial, allowing immediate and direct reading of the hardness value.Q: What materials can be tested with this Rockwell Hardness Tester?

A: This device is designed for determining the hardness of various metals and alloys. Different indentersdiamond cone and steel ballenable testing across Rockwell scales (HRA, HRB, HRC) as applicable to a wide range of metallic materials.Q: When and where is this tester most effectively used?

A: The Rockwell Hardness Tester is commonly used in industrial, metallurgical, and research laboratories for routine or batch testing, quality control, and material characterization. Its robust design and bench-top mounting make it suitable for environments requiring repeated, reliable hardness measurements.Q: What is the process for conducting a Rockwell hardness test on this equipment?

A: Begin by placing a cleaned and properly sized specimen (up to 230 mm height) on the test platform. Select the appropriate indenter and test force for the material. Apply the preliminary force, then the major test force, and take the reading directly from the analogue dial as per standard Rockwell testing procedures.Q: How does this tester ensure accuracy and reliability?

A: The cast iron housing provides mechanical stability, while the manual loading/unloading minimizes test variability. The analogue display offers a resolution of 0.1 HRC and accuracy of 1 HRC. Consistent test speed and forces further improve reliability in measurement.Q: What are the key benefits of using this hardness tester?

A: Key benefits include rugged construction for long-term reliability, precise manual control for accurate results, direct and easy-to-read analogue measurement, and versatility in handling a range of sample sizes and hardness scales. The unit is also resistant to high humidity (up to 85% RH) and operates efficiently across 10C to 40C.

More Products in Rockwell Hardness Tester Category

Touch Screen Load Cell Based Rockwell Hardness Tester (Heavy Duty)

Minimum Order Quantity : 1 Number

Machine Weight : 120 kg (approx)

Application : Hardness Testing of Metals and Alloys

Rockwell Hardness Tester

Price Range 29000.00 - 145000.00 INR

Minimum Order Quantity : 1 Unit

Machine Weight : 50150 Kilograms (kg)

Application : Industrial

Color : White & Blue

Rockwell Hardness Tester

Price Range 29000.00 - 40000.00 INR

Minimum Order Quantity : 1 Unit

Machine Weight : 100 Kilograms (kg)

Application : Industrial

Color : White &Blue

Economical Digital Rockwell Hardness Tester.

Minimum Order Quantity : 1 Number

Machine Weight : 65 Kilograms (kg)

Dimension (L*W*H) : 630x238x466 Millimeter (mm)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry