Touch Screen Load Cell Based Rockwell Hardness Tester (Heavy Duty)

Touch Screen Load Cell Based Rockwell Hardness Tester (Heavy Duty) Specification

- Gas Pressure

- 0.6 MPa (for pneumatic models)

- Hardness

- Rockwell Scale (HRB, HRC, HRA)

- Max Height

- 220 mm

- Accuracy

- ±1 Rockwell Unit

- Equipment Type

- Rockwell Hardness Tester (Heavy Duty)

- Operating Voltage

- 220V ±10%, 50/60Hz

- Display Type

- 7 Touch Screen LCD

- Frequency

- 50/60 Hz

- Specimen Size

- 2-70 mm height, 10-70 mm diameter

- Port Size

- Standard 1/4 inch

- Interface Type

- USB, RS-232

- Temperature

- 10°C to 40°C

- Power Supply

- 220V ±10% AC, 50Hz

- Humidity

- ≤ 65% RH

- Resolution

- 0.1 HR

- Response Time

- ≤2 sec

- Application

- Hardness Testing of Metals and Alloys

- Measuring Range

- 20-100 HRB, 20-70 HRC

- Automation Grade

- Semi-Automatic

- Test Range

- 20-100 HRB / 20-70 HRC

- Mounting Type

- Bench-top

- Number of Specimens

- Multiple (as per requirement)

- Features

- Automatic loading/unloading, data storage, user calibration

- Usage

- Industrial / Laboratory

- Capacity

- 60, 100, 150 kgf

- Machine Weight

- 120 kg (approx)

- Test Speed

- 0.5 - 3 mm/s adjustable

- Test Width

- 160 mm

- Test Stroke

- 220 mm (max)

- Control Mode

- Touch Screen Load Cell Based

Touch Screen Load Cell Based Rockwell Hardness Tester (Heavy Duty) Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Touch Screen Load Cell Based Rockwell Hardness Tester (Heavy Duty)

Features

Fully automatic high-speed response closed-loop sensor loading system, moving the platform as a whole, realizing high-precision and fast testing to improve the control accuracy of the actuator.

Load cell based.

Touch screen operation.

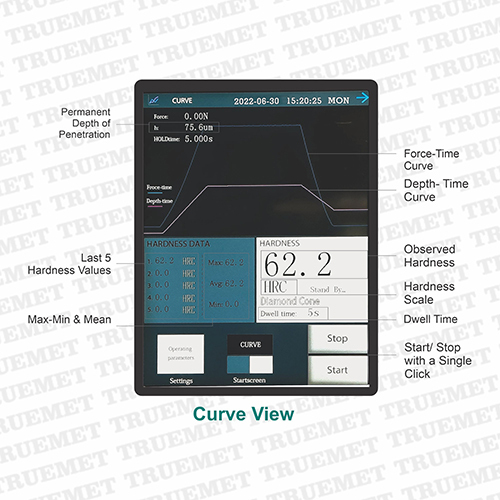

Real time display for Force-Time & Depth-Time curve.

Testing Cycle starts just after touching the specimen with indenter (no need to apply initial test force).

GO/NG tolerance judgement.

Hardness scale conversion HR, HB, HV.

Built-in thermal printer.

Load/Scale selection through touch panel.

Built-in flexible illumination light source to focus light on test area.

Permanent depth of penetration displayed on screen.

Robust and Accurate Hardness Testing

This heavy duty Rockwell Hardness Tester boasts a sturdy cast iron construction for enhanced durability and vibration resistance. Its touch screen load cell-based control assures precision, and in-built calibration maintains accuracy within 1 Rockwell Unit. Suitable for a variety of specimen sizes, the tester covers HRB and HRC scales, adhering to key international standards for reliable results every time.

Comprehensive Data Handling and Reporting

Equipped with internal memory to store up to 1000 test results, this device supports efficient data management. Users can print instant reports with the integrated thermal printer or export results via USB/RS232 ports for further analysis. The multi-language interface on the 7" LCD touch screen simplifies operation for diverse teams and environments.

Enhanced Safety and Ease of Use

The Rockwell Hardness Tester includes overload protection for safe operation, and LED illumination improves visibility within the specimen area for precise positioning. Automatic loading and unloading reduce manual effort, and touch-based controls quicken setup. User calibration mode ensures sustained measurement reliability, supporting industrial and laboratory requirements.

FAQs of Touch Screen Load Cell Based Rockwell Hardness Tester (Heavy Duty):

Q: How does the Rockwell Hardness Tester ensure measurement accuracy?

A: The tester uses precise load cell technology and provides user calibration mode, guaranteeing accuracy within 1 Rockwell Unit. Compliance with ASTM E18 and ISO 6508 standards further validates its measurement reliability.Q: What is the process for exporting test reports from the device?

A: Reports can be exported via USB or RS-232 ports. After completing a test and saving the results in internal memory, simply connect a compatible device to access and transfer the data for analysis or documentation.Q: When should user calibration be performed on this hardness tester?

A: User calibration should be conducted during initial setup, after prolonged use, or whenever measurement accuracy is in question, using the in-built calibration mode accessible from the touch screen interface.Q: Where can this hardness tester be utilized?

A: It is suitable for industrial and laboratory settings, ideal for hardness testing of metals and alloys across manufacturing, quality control, research, and educational environments.Q: What are the benefits of the integrated thermal printer?

A: The built-in thermal printer allows users to generate instant hardcopy test reports, improving result documentation and reducing wait times for data output.Q: How does the overload protection feature work?

A: The tester is engineered with overload protection, which automatically intervenes to prevent damage to the load cell and specimen during testing, ensuring equipment longevity and user safety.Q: What specimen sizes and test ranges are supported?

A: The device accommodates specimens between 270 mm in height and 1070 mm in diameter, with a test range of 20100 HRB and 2070 HRC, making it versatile for various metal and alloy types.

More Products in Rockwell Hardness Tester Category

Rockwell Hardness Tester (Weight Type)

Minimum Order Quantity : 1 Number

Voltage : DC 5 Volt (v)

Application : Determination of Rockwell Hardness of Metals and Alloys

Machine Weight : 65 Kilograms (kg)

Dimension (L*W*H) : 630x238x466 Millimeter (mm)

Rockwell Hardness Tester

Price Range 29000.00 - 40000.00 INR

Minimum Order Quantity : 1 Unit

Voltage : 220280 Volt (v)

Application : Industrial

Machine Weight : 100 Kilograms (kg)

Rockwell Hardness Tester

Price Range 29000.00 - 145000.00 INR

Minimum Order Quantity : 1 Unit

Voltage : 220 Volt (v)

Application : Industrial

Machine Weight : 50150 Kilograms (kg)

Economical Digital Rockwell Hardness Tester.

Minimum Order Quantity : 1 Number

Voltage : DC 5V Volt (v)

Machine Weight : 65 Kilograms (kg)

Dimension (L*W*H) : 630x238x466 Millimeter (mm)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry