Computerized Load Cell Based Vickers Hardness Tester (THT-Series with VIDAS 2.0)

Price 1 INR/ Number

Computerized Load Cell Based Vickers Hardness Tester (THT-Series with VIDAS 2.0) Specification

- Mounting Type

- Bench Top

- Temperature

- 10–35°C

- Resolution

- 0.1 HV

- Frequency

- 50-60 Hz

- Equipment Type

- Vickers Hardness Tester

- Accuracy

- ±1%

- Interface Type

- USB/RS232

- Humidity

- ≤75% RH

- Automation Grade

- Fully Automatic

- Specimen Size

- Up to 200 mm width

- Port Size

- Standard USB

- Test Range

- 5–3000 HV

- Number of Specimens

- Multiple

- Display Type

- Touchscreen Display

- Features

- Load cell based, motorized turret, automatic indentation measurement, automated report generation

- Operating Voltage

- AC 220V ±5%

- Hardness

- Vickers (HV)

- Response Time

- <2 sec

- Power Supply

- AC220V±5% 50-60Hz

- Max Height

- 150 mm

- Measuring Range

- 5–3000 HV

- Dimension (L*W*H)

- 585X200X630 Millimeter (mm)

- Application

- Material hardness testing (metals, alloys, coatings)

- Usage

- Laboratory and Industrial

- Capacity

- Single Specimen up to 100 kg

- Machine Weight

- 42 Kilograms (kg)

- Test Speed

- Standard

- Test Width

- 200 mm

- Test Stroke

- 0–50 mm

- Control Mode

- Computerized (VIDAS 2.0 software)

Computerized Load Cell Based Vickers Hardness Tester (THT-Series with VIDAS 2.0) Trade Information

- Minimum Order Quantity

- 1 Millimeter

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Millimeter Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Computerized Load Cell Based Vickers Hardness Tester (THT-Series with VIDAS 2.0)

Features

MANUAL EYEPIECE : Equipped with 10x Manual Eyepiece to measure the length of diagonal. The hardness value can be displayed directly on LCD screen by entering the indentation diagonal length.

CAMERA PORT : Machine equipped with dual optical channel. 5 MP USB Camera is connected to one of the dual optical channels, other optical channel is for 10X eyepiece. Both optical channel works simultaneously.

ILLUMINATION SYSTEM : Halogen illumination unit gives very clear images and can be also used as a simple microscope. Halogen illumination unit enter stand by mode after a certain period of inactivity which gives it a long service life and low power consumption.

TEST FORCE : All the test force is applied by load cell. The high quality load sensing system can do a wide-range of vickers test by one load cell.

LCD SCREEN : 80X25mm LCD Screen can visually display the hardness value, conversion hardness, test force and dwell time.

TURRET MECHANISM : Equipped with manual turret mechanism. The position of the indentor and objective lens can be switched manually.

EMERGENCY SWITCH : Equipped with emergency stop switch.

Precision and Automation in Hardness Testing

The THT-Series Vickers Hardness Tester redefines efficiency in material hardness analysis through automatic load control and a motorized turret. With motor-driven specimen positioning and instant digital image capture, it streamlines workflow while ensuring accurate and repeatable readings. Users benefit from rapid automatic indentation measurement and report generation through integrated VIDAS 2.0 software, reducing operator error and maximizing productivity.

User-Friendly Operation and Data Management

Featuring a large touchscreen display and intuitive VIDAS 2.0 interface, the machine simplifies test setup, measurement, and data analysis. Data can be stored onboard or exported via USB or RS232 interfaces to a PC, enabling seamless documentation and further analysis. The robust storage and connectivity options make it suitable for both standalone and networked laboratory environments.

Advanced Safety and Compliance

Safety is integral to the THT-Series design, with built-in emergency stop and overload protection systems, as well as both automatic and manual calibration functionality. Compliance with international standards (ASTM E92, ISO 6507) ensures test results are universally recognized, supporting quality control and research in varied industrial and laboratory settings.

FAQs of Computerized Load Cell Based Vickers Hardness Tester (THT-Series with VIDAS 2.0):

Q: How does the automatic load cell-based control system improve the testing process?

A: The closed-loop automatic load cell control guarantees precise and stable application of test loads between 10g and 2kg. This enables highly accurate and repeatable hardness measurements, reducing human error and enhancing consistency throughout multiple tests.Q: What are the benefits of the motorized 6-position turret in this hardness tester?

A: The motorized turret automates the exchange of objectives and indenters, minimizing manual intervention. This allows rapid switching between test setups, increasing productivity and reducing the risk of handling errors during repetitive or high-volume testing.Q: When is the computerized Vickers Hardness Tester most effectively used?

A: This instrument is ideal for laboratories and industrial settings where precise, repeatable hardness measurements of metals, alloys, and coatings are required. Its broad test load range and automated features make it especially valuable in research, quality control, and material development environments.Q: Where can test data be stored and how can it be accessed?

A: Test data can be saved both onboard the machine and externally when connected to a PC. The system supports USB and RS232 interfaces, allowing for easy transfer and backup of test results, reports, and images for detailed analysis and record-keeping.Q: What is the process of measuring hardness with this tester?

A: Specimens are mounted on the bench, and the system automatically applies the desired load, creates indentations, and captures images via the integrated CCD camera. The software (VIDAS 2.0) then analyzes and calculates hardness values, displaying the results on the touchscreen and generating comprehensive reports.Q: How does the VIDAS 2.0 software enhance analysis and reporting?

A: VIDAS 2.0 automates optical measurement, calculation, and report generation, ensuring quick and accurate results. Its certified algorithms provide reliable, standards-compliant analyses, while the user-friendly interface simplifies data handling and export.Q: What safety features are included in the THT-Series Vickers Hardness Tester?

A: The tester includes emergency stop and overload protection mechanisms to safeguard users and the machine. These features help prevent damage during operation, ensuring safe and uninterrupted testing even in demanding environments.

More Products in Vicker Hardness Tester Category

Computerized Load Cell Based Digital Vickers Hardness Tester (THT-D Series with VIDAS 2.0)

Minimum Order Quantity : 1 Millimeter

Application : Hardness testing of ferrous, nonferrous metals, ceramics, composites

Machine Weight : 42 Kilograms (kg)

Test Width : Accommodates specimen widths up to 130 mm

Control Mode : Computerized Control

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

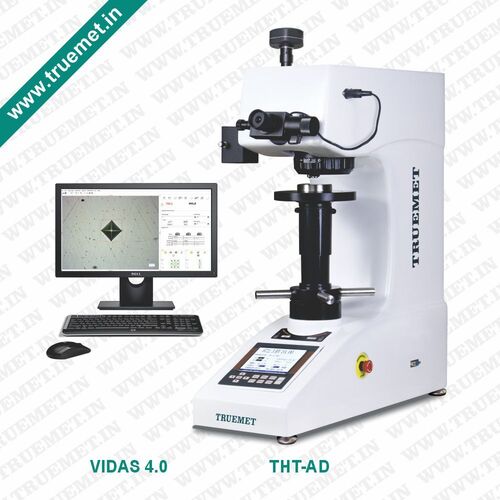

Computer Controlled Load Cell Based Digital Vickers Hardness Tester (THT-AD SERIES with VIDAS 4.0)

Minimum Order Quantity : 1 Millimeter

Application : Metallurgical microhardness measurement, Case Depth Analysis

Machine Weight : 42 Kilograms (kg)

Test Width : 200 mm

Control Mode : ComputerControlled, Fully Automatic

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Digital Touch Screen Vickers Hardness Tester (VHT-DT Series)

Minimum Order Quantity : 1 Number

Application : Metallographic analysis, hardness measurement of metals, ceramics, composite materials

Machine Weight : 42 Kilograms (kg)

Test Width : Max 95 mm

Control Mode : Digital Touch Screen

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

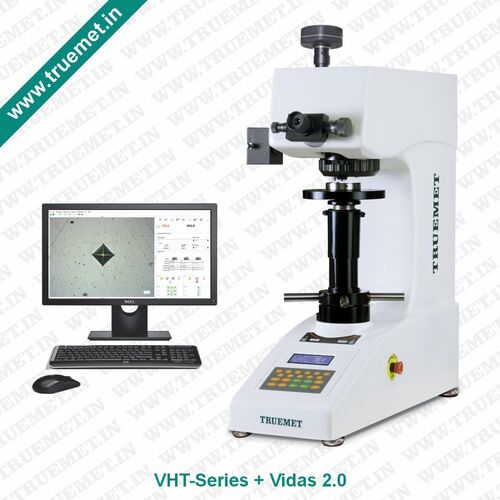

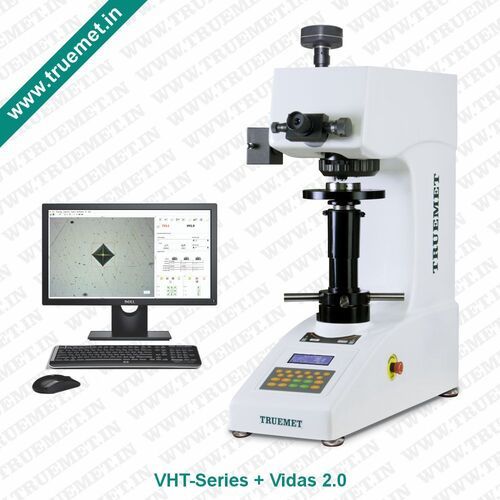

Vickers Hardness Tester (VHT-Series with Vidas 2.0)

Minimum Order Quantity : 1 Number

Application : Suitable for thin sheet, surface/carburized, coating and micro components

Machine Weight : 42 Kilograms (kg)

Test Width : Maximum 130 mm

Control Mode : Touch screen control via Vidas 2.0 software

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry