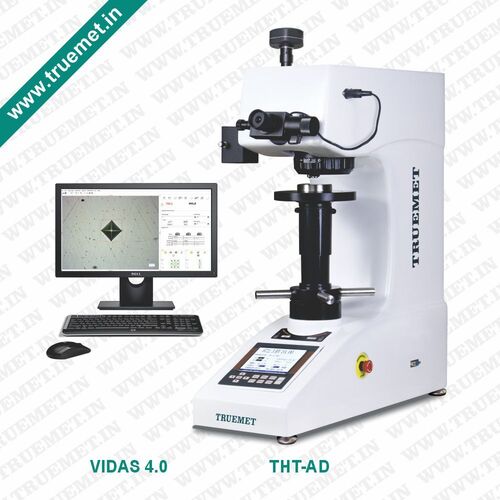

Computer Controlled Load Cell Based Digital Vickers Hardness Tester (THT-AD SERIES with VIDAS 4.0)

Computer Controlled Load Cell Based Digital Vickers Hardness Tester (THT-AD SERIES with VIDAS 4.0) Specification

- Application

- Metallurgical microhardness measurement, Case Depth Analysis

- Temperature

- 10°C ~ 35°C

- Accuracy

- ±1%

- Frequency

- 50-60Hz

- Automation Grade

- Full Automatic

- Humidity

- ≤85% RH

- Power Supply

- AC220V±5% 50-60Hz

- Dimension (L*W*H)

- 585X200X630 Millimeter (mm)

- Specimen Size

- Up to 200 mm width

- Interface Type

- USB, LAN, RS232

- Mounting Type

- Bench-top

- Test Range

- 5g ~ 2kg (Load Cell based)

- Features

- Load Cell Technology, Auto Turret, Auto Focusing, Digital Reading, Real-Time Data Transfer, Image Analysis, Report Generation

- Response Time

- <1 second

- Max Height

- 630 mm

- Operating Voltage

- 220V AC

- Measuring Range

- 10 HV ~ 3000 HV

- Display Type

- VIDAS 4.0 Touchscreen / On-PC Display

- Hardness

- Vickers Microhardness

- Port Size

- USB, LAN

- Number of Specimens

- Multiple (as per application)

- Resolution

- 0.01 HV

- Equipment Type

- Digital Vickers Hardness Tester

- Usage

- Microhardness Testing on Metals, Ceramics, Composites

- Capacity

- High repeatability and reliability

- Machine Weight

- 42 Kilograms (kg)

- Test Speed

- Programmable (adjustable via software)

- Test Width

- 200 mm

- Test Stroke

- 0~35 mm

- Control Mode

- Computer-Controlled, Fully Automatic

Computer Controlled Load Cell Based Digital Vickers Hardness Tester (THT-AD SERIES with VIDAS 4.0) Trade Information

- Minimum Order Quantity

- 1 Millimeter

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Millimeter Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Computer Controlled Load Cell Based Digital Vickers Hardness Tester (THT-AD SERIES with VIDAS 4.0)

Features

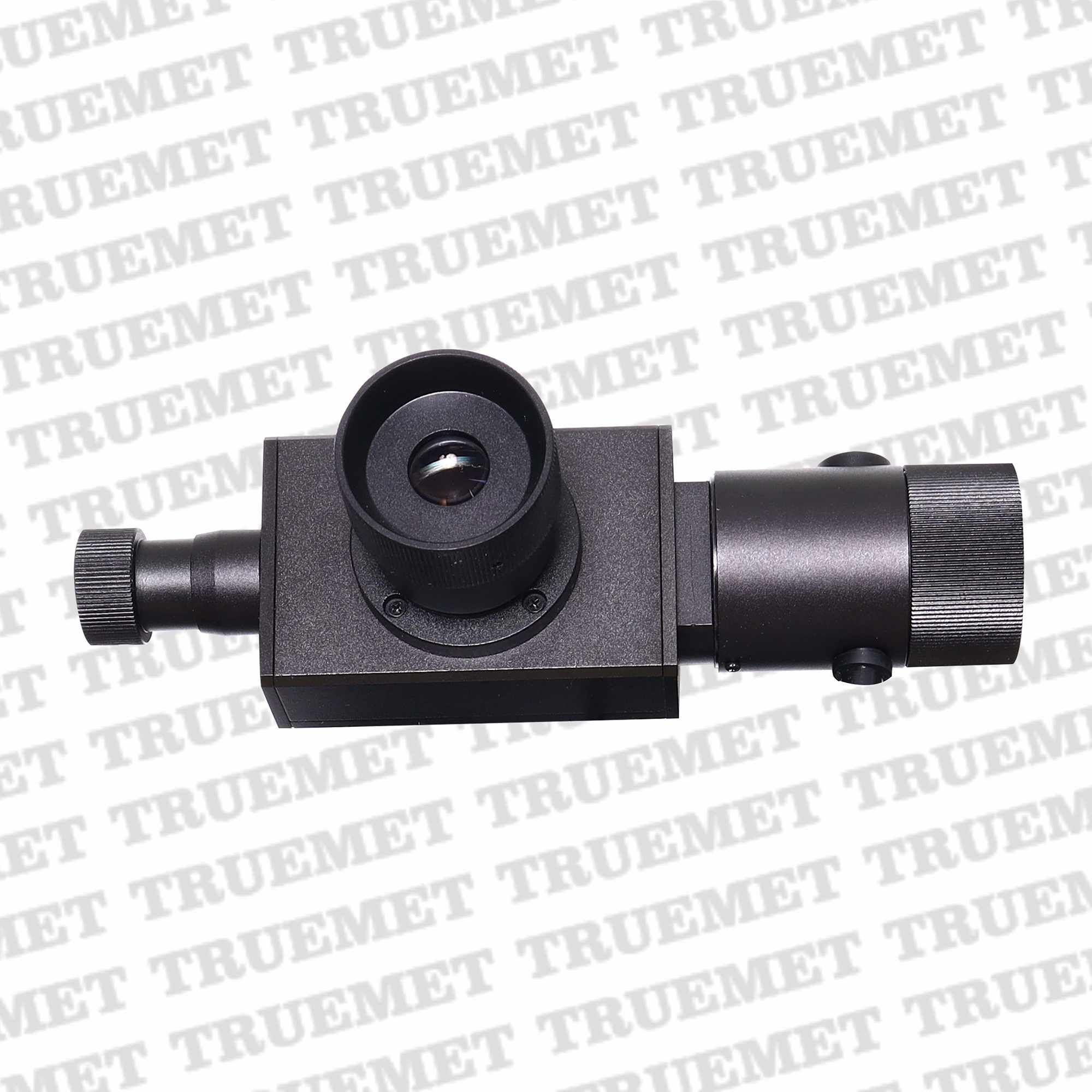

DIGITAL EYEPIECE : Equipped with 10x Digital Eyepiece to directly measure the length of the diagonal. The hardness value can be displayed directly and there is no need to enter the length of the diagonal.

ILLUMINATION SYSTEM : Halogen illumination unit gives very clear images and can be also used as a simple microscope. Halogen illumination unit enter stand by mode after a certain period of inactivity which gives it a long service life and low power consumption.

DATA OUTPUT : Equipped with built in thermal printer to take the print out the hardness result.

CAMERA PORT : Machine equipped with dual optical channel. 5 MP USB Camera is connected to one of the dual optical channels, other optical channel is for 10X eyepiece. Both optical channel works simultaneously.

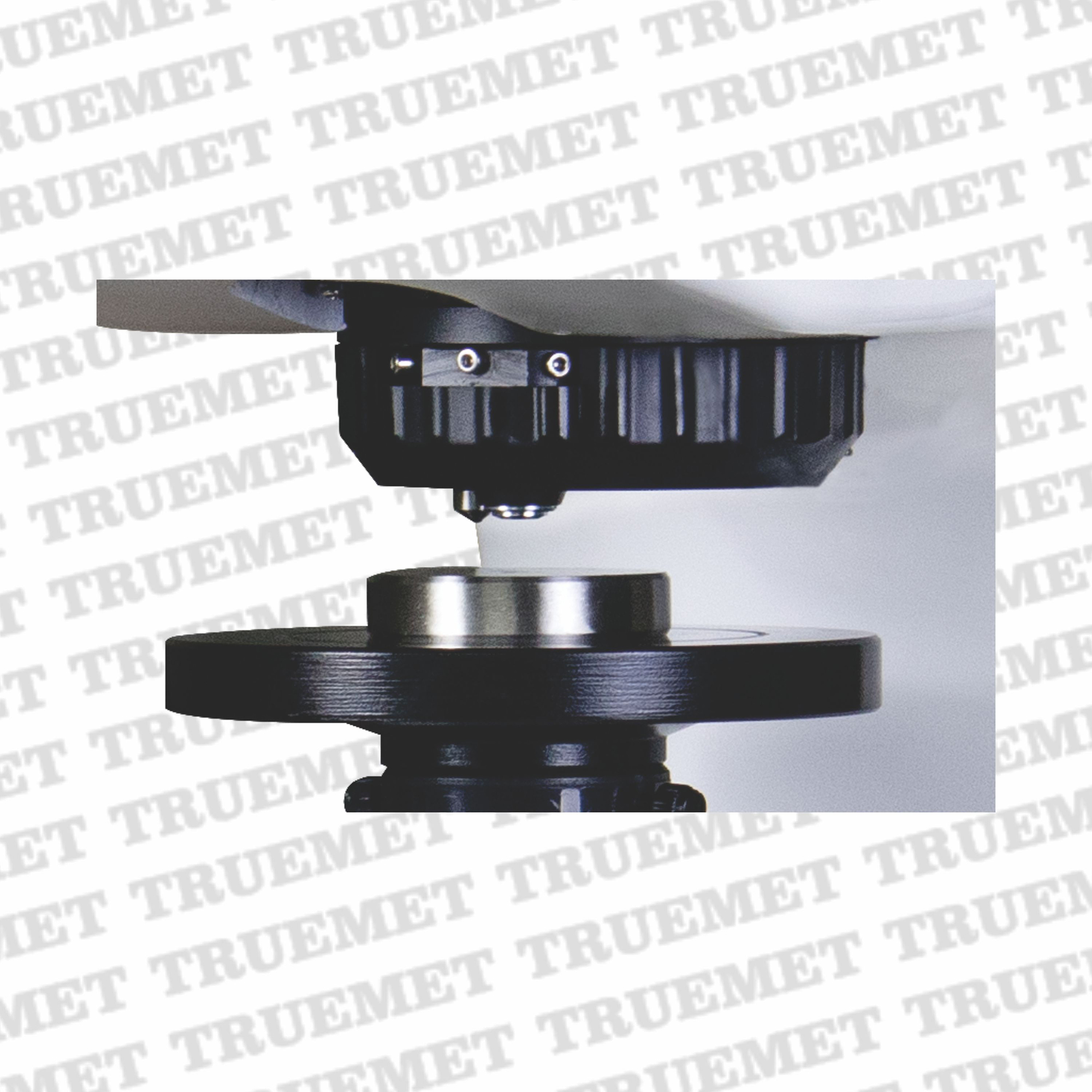

TEST FORCE : All the test force is applied by load cell. The high quality load sensing system can do a wide-range of vickers test by one load cell.

AUTO TURRET MECHANISM : Equipped with auto turret mechanism. Auto turret perform a series of operation and measuring lens automatically comes back to central position after making indentation. The position of the indenter and the objective lens can be automatically switched using keypad.

LARGE LCD SCREEN PANEL : 75X100 mm LCD screen can visually display the hardness value, conversion hardness, test force, dwell time, upper & lower limit, max-min, and average value.

EMERGENCY SWITCH : Equipped with emergency stop switch.

Advanced Digital Hardness Testing

Leveraging cutting-edge load cell technology, the THT-AD SERIES delivers highly accurate Vickers hardness measurements with a broad load range (5g to 2kg). The advanced VIDAS 4.0 system provides intuitive touchscreen and PC-based control, enabling full automation, precise digital readouts, and consistent, reliable data. Its innovative combination of automatic sample focusing, programmable stage motion, and auto turret ensures efficiency and versatility for a variety of microhardness applications.

Seamless Automation and User Control

Engineered for maximum user convenience, this tester automates critical tasks like sample focusing, indenter selection, and data capture. The software enables programmable XY stage movement, automatic reporting, and statistical analysis, minimizing human intervention and reducing errors. The system is suitable for high-volume laboratories seeking to optimize workflow and quality assurance processes with advanced safety, stability, and diagnostics features.

FAQs of Computer Controlled Load Cell Based Digital Vickers Hardness Tester (THT-AD SERIES with VIDAS 4.0):

Q: How does the THT-AD SERIES ensure accurate Vickers hardness measurements?

A: The tester employs load cell technology with digital auto calibration, ensuring precise force application from 5g to 2kg. Advanced features such as automatic focusing, auto turret, and high-resolution imaging further guarantee accurate and repeatable hardness readings, aligned with ASTM E384 and ISO 6507 standards.Q: What sample types and sizes can be tested with this Digital Vickers Hardness Tester?

A: The tester accommodates metals, ceramics, and composites with specimen widths up to 200 mm and a programmable XY stage for multiple samples, making it suitable for both research and industrial applications.Q: When is automated stage movement or focusing used in testing?

A: Automated XY stage movement and auto-focusing are utilized during high-throughput testing or when precise, repeatable measurements are required, reducing operator involvement and increasing overall testing efficiency.Q: Where is data from the hardness tests stored and how can it be accessed?

A: All test data and captured images are stored digitally, accessible on the VIDAS 4.0 touchscreen or PC. Users can export results in Excel, PDF, and common image formats via USB, LAN, or RS232 interfaces for easy reporting and analysis.Q: What is the process for calibrating the THT-AD SERIES Vickers Hardness Tester?

A: Calibration is fully digital and automated, performed via the integrated software system. The process ensures the applied force and measurement system maintain accuracy over time, in compliance with international standards.Q: How does the system support remote diagnostics and user safety?

A: With built-in remote diagnostics, service support is available without on-site visits. Safety features such as overload protection and alert systems further ensure safe and reliable usage, protecting both users and the instrument.Q: What are the main benefits of using this computer-controlled hardness tester?

A: Users benefit from high accuracy (1%), rapid test response (<1 second), versatile automation, advanced reporting capabilities, reduced operator workload, and reliable performance even in varying laboratory environments due to temperature and vibration compensation.

More Products in Vicker Hardness Tester Category

Computerized Load Cell Based Digital Vickers Hardness Tester (THT-D Series with VIDAS 2.0)

Minimum Order Quantity : 1 Millimeter

Machine Weight : 42 Kilograms (kg)

Power Supply : AC220V±5% 5060Hz

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Control Mode : Computerized Control

Test Stroke : Max Up/Down travel: 50 mm

Computerized Digital Touch Screen Vickers Hardness Tester (VHT-ADT Series with VIDAS 4.0)

Minimum Order Quantity : 1 Number

Machine Weight : 42 Kilograms (kg)

Power Supply : AC220V±5% 5060Hz

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Control Mode : Digital Touch Screen with VIDAS 4.0 Automation

Test Stroke : Up to 100 mm

Computerized Digital Touch Screen Vickers Hardness Tester (VHT-ADT Series with VIDAS 2.0)

Minimum Order Quantity : 1 Number

Machine Weight : 42 Kilograms (kg)

Power Supply : AC220V±5% 5060Hz

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Control Mode : Digital Touch Screen (Computerized)

Test Stroke : 0100 mm

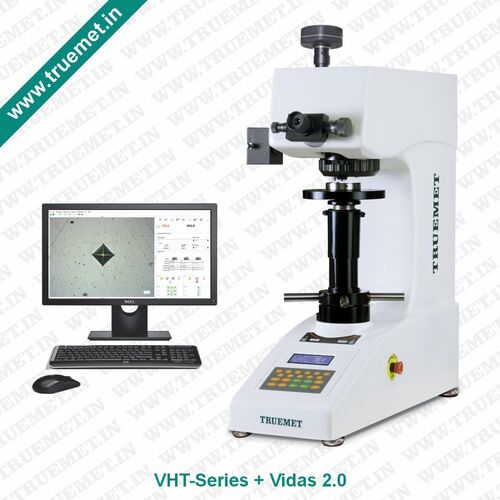

Vickers Hardness Tester (VHT-Series with Vidas 2.0)

Minimum Order Quantity : 1 Number

Machine Weight : 42 Kilograms (kg)

Power Supply : AC220V±5% 5060Hz

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Control Mode : Touch screen control via Vidas 2.0 software

Test Stroke : 0 ~ 60 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry