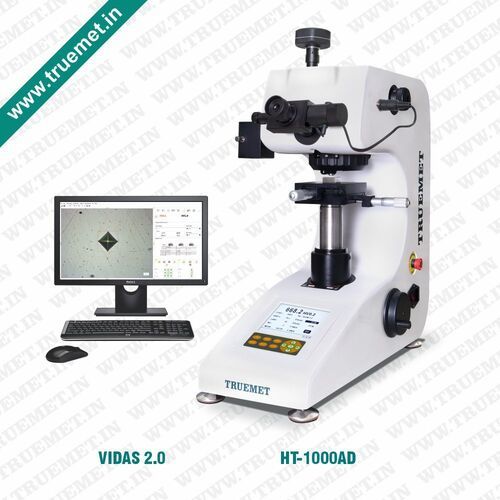

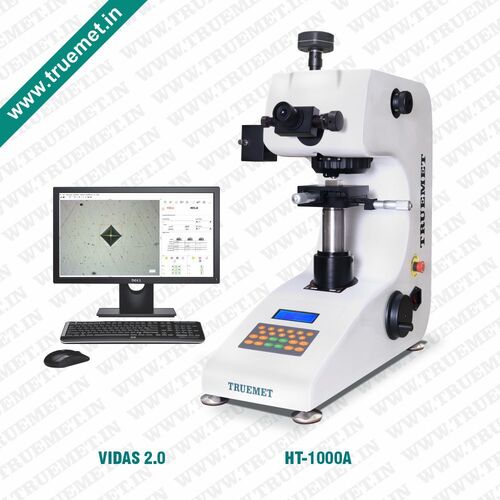

Computerized Micro Vickers Hardness Tester (HT-1000A with VIDAS 2.0)

Price 1 INR/ Number

Computerized Micro Vickers Hardness Tester (HT-1000A with VIDAS 2.0) Specification

- Power Supply

- AC220V±5% 50-60Hz

- Operating Voltage

- 220V AC

- Max Height

- 100 mm (specimen mounting height)

- Accuracy

- ±1.0% of full scale

- Interface Type

- USB, RS232

- Frequency

- 50/60 Hz

- Mounting Type

- Bench-top

- Resolution

- 0.01 μm (via digital eyepiece and camera)

- Equipment Type

- Computerized Micro Vickers Hardness Tester

- Automation Grade

- Fully Automatic with VIDAS 2.0 software

- Measuring Range

- 1 HV ~ 2967 HV

- Hardness

- Micro Vickers (VHN/HV)

- Features

- Automated loading, image analysis, data logging, auto-turret, high-precision optics

- Number of Specimens

- Single specimen per test cycle

- Display Type

- 7 Color LCD and PC-based graphical interface

- Specimen Size

- Up to 95 mm wide, max 100 mm high

- Application

- Precision hardness measurement of micro-components, metals, and alloys

- Port Size

- Standard USB and serial ports (for data transfer and control)

- Humidity

- ≤85% RH

- Temperature

- 10°C ~ 35°C (operation)

- Response Time

- < 1 Second (measurement readout)

- Dimension (L*W*H)

- 530X200X530

- Test Range

- 5 gf to 1000 gf (Micro Vickers)

- Usage

- Laboratory materials analysis

- Capacity

- 1000 gf Max test force

- Machine Weight

- 35 Kilograms (kg)

- Test Speed

- Customizable according to VIDAS 2.0 software setting

- Test Width

- Up to 95 mm (as per standard specimen stage)

- Test Stroke

- Up to 60 mm

- Control Mode

- Fully Computerized

Computerized Micro Vickers Hardness Tester (HT-1000A with VIDAS 2.0) Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Computerized Micro Vickers Hardness Tester (HT-1000A with VIDAS 2.0)

FeaturesMANUAL EYEPIECE :Equipped with 10x Manual Eyepiece to measure the length of diagonal. The hardness value can be displayed directly on LCD screen by entering the indentation diagonal length.

CAMERA PORT :Machine equipped with dual optical channel. 5 MP USB Camera is connected to one of the dual optical channels, other optical channel is for 10X eyepiece. Both optical channel works simultaneously.

ILLUMINATION SYSTEM :Halogen illumination unit gives very clear images and can be also used as a simple microscope. Halogen illumination unit enter stand by mode after a certain period of inactivity which gives it a long service life and low power consumption.

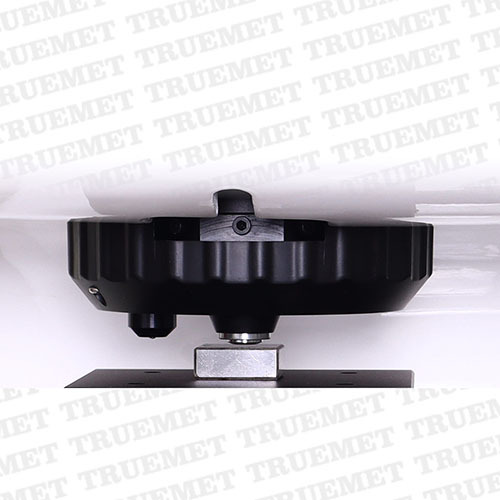

TEST FORCE : Wide range of test fore (10gm to 1000gm) can be selected with external force selection knob. The test force is automatically displayed on the LCD display.

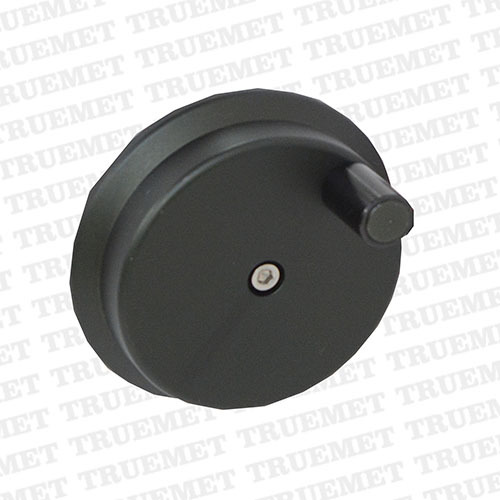

AUTO TURRET MECHANISM :Equipped with auto turret mechanism. Auto turret perform a series of operation and measuring lens automatically comes back to central position after making indentation. The position of the indenter and the objective lens can be automatically switched using keypad.

Z-AXIS LIFTING SYSTEM :Side-Ways lifting system makes the z-axis movement more stable and accurate.

LCD SCREEN :80X25mm LCD Screen can visually display the hardness value, conversion hardness, test force and dwell time.

EMERGENCY SWITCH :Equipped with emergency stop switch.

Advanced Optical Measurement Technology

The HT-1000A harnesses dual objective lenses and an automatic turret for rapid, precise focusing. Its integrated high-resolution digital camera and bright LED lighting assure clear indentation imaging. The system automatically measures indentations using sophisticated optical analysis, delivering consistent accuracy and minimizing operator error during micro-hardness testing.

User-Friendly Automation and Software

Equipped with fully motorized, computerized controls and the VIDAS 2.0 software suite, this tester automates load selection, turret switching, and measurement routines. The intuitive interface supports multiple languages and allows real-time data analysis, easy storage, and export of test results, significantly streamlining laboratory workflows.

Versatile and Comprehensive Performance

Designed to accommodate specimens up to 95 mm wide and 100 mm high, the HT-1000A covers a measuring range of 1 HV to 2967 HV. It ensures measurement accuracy within 1.0% of full scale and provides rapid test readouts. Its benchtop design, robust construction, and USB/RS232 connectivity make it adaptable for a range of micro-hardness applications.

FAQs of Computerized Micro Vickers Hardness Tester (HT-1000A with VIDAS 2.0):

Q: How does the HT-1000A perform automated hardness measurements?

A: The HT-1000A uses advanced optics, a high-resolution camera, and VIDAS 2.0 software for fully automated indentation measurements. Simply place the specimen, set parameters via software, and the system motorizes the load application, switches objectives automatically, and records results with high accuracy.Q: What benefits does VIDAS 2.0 software offer for data handling?

A: VIDAS 2.0 provides integrated storage, real-time analysis, and flexible data export. It streamlines workflows by allowing lab users to review, analyze, and archive results easily, and offers multi-language support for wider accessibility.Q: Where can this hardness tester be effectively utilized?

A: This equipment is ideal for laboratory material analysis, especially in research, quality control, and educational institutions requiring precise micro-hardness measurements of metals, alloys, and micro-components.Q: What are the maximum specimen dimensions and test force?

A: The HT-1000A accommodates specimens up to 95 mm wide and 100 mm high. It supports a maximum test force of 1000 gf, making it suitable for various sample types within the micro Vickers testing range.Q: When should I use the dual objective (10x/40x) feature?

A: The dual objective lenses are automatically selected based on optimal viewing needs. Use 10x for wider field visualization and 40x for detailed examination of indentation, both auto-switched via the motorized turret for precision.Q: How is specimen illumination achieved during testing?

A: A high-intensity LED provides uniform and bright illumination for clear imaging, ensuring accurate measurement of the Vickers indentations regardless of the samples reflectivity.Q: What are the primary benefits of full automation in this device?

A: Full automation minimizes user intervention, reduces error, and increases repeatability. The system handles load selection, lens switching, measurement, and data logging, enhancing productivity and reliability in high-throughput testing environments.

More Products in Micro Vicker Hardness Tester Category

Auto Turret Micro Vickers Hardness Tester (HT-1000A)

Price 1 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 530X200X530 Millimeter (mm)

Test Range : 1HV~2967HV

Response Time : <2s

Temperature : 10°C 30°C

Digital Touch Screen Micro Vickers Hardness Tester (HT-1000DT with Vidas 2.0)

Price 1 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 530X200X530 Millimeter (mm)

Test Range : 1HV~3000HV

Response Time : ≤1s

Temperature : 10°C to 35°C

Digital Touch Screen Micro Vickers Hardness Tester (HT-1000ADT)

Price 1 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 530X200X530 Millimeter (mm)

Test Range : 1HV – 2967HV

Response Time : Instantaneous digital readout

Temperature : Operating: 10°C 35°C

Computerized Digital Micro Vickers Hardness Tester (HT-1000AD with VIDAS 2.0)

Price 1 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 530X200X530 Millimeter (mm)

Test Range : 1HV – 3000HV

Response Time : Instant digital reading (within 1 sec)

Temperature : 10°C – 35°C operating range

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry