Vickers Hardness Tester (VHT Series)

Price 1 INR/ Number

Vickers Hardness Tester (VHT Series) Specification

- Weight

- 42 Kilograms (kg)

- Power Supply

- AC220V±5% 50-60Hz

- Test Range

- 1-4500 HV

- Dimension (L*W*H)

- 585X200X630 Millimeter (mm)

- Machine Weight

- 42 Kilograms (kg)

Vickers Hardness Tester (VHT Series) Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Vickers Hardness Tester (VHT Series)

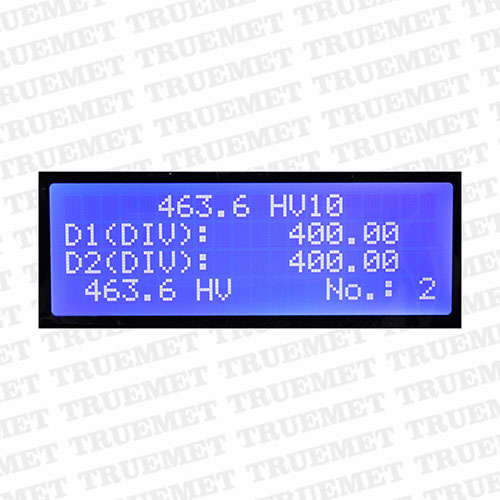

FeaturesMANUAL EYEPIECE :Equipped with 10x Manual Eyepiece to measure the length of diagonal. The hardness value can be displayed directly on LCD screen by entering the indentation diagonal length.

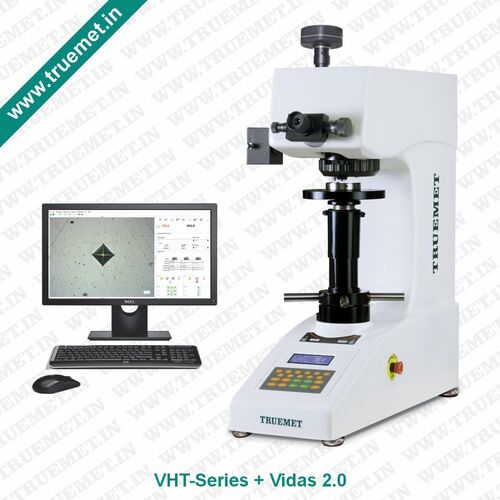

CAMERA PORT :Machine equipped with dual optical channel, one optical channel for 10X eyepiece and another optical channel is for camera by which machine can be upgraded into computerized model. Both optical channel works simultaneously.

ILLUMINATION SYSTEM :Halogen illumination unit gives very clear images and can be also used as a simple microscope. Halogen illumination unit enter stand by mode after a certain period of inactivity which gives it a long service life and low power consumption.

TURRET MECHANISM :Equipped with manual turret mechanism. The position of the indentor and objective lens can be switched manually.

LCD Screen :80X25mm LCD Screen can visually display the hardness value, conversion hardness, test force and dwell time.

TEST FORCE :Wide range of test force can be selected with external force selection knob. The test force is automatically displayed on the 80X25mm LCD Screen.

EMERGENCY SWITCH :Equipped with emergency stop switch.

Advanced Hardness Measurement

Experience precise and reliable hardness testing with the Vickers Hardness Tester VHT Series. Engineered for a broad range of applications, its comprehensive test capability covers values from 1 to 4500 HV, ensuring suitability for various metals and alloys. The machine is designed for consistent, repeatable results, making it indispensable in research, manufacturing, and quality control settings.

Compact and Sturdy Design

The VHT Series combines a compact footprint (585x200x630 mm) with a robust build, weighing 42 kilograms. Its design supports both portability within labs and stability for accurate measurements. The machines durable construction minimizes vibration, enhancing the repeatability of test results while fitting conveniently in most workspaces.

FAQs of Vickers Hardness Tester (VHT Series):

Q: How is the Vickers Hardness Tester (VHT Series) operated during testing?

A: The tester requires connecting to a standard AC220V5% 50-60Hz outlet. Sample placement involves positioning the material on the stage, adjusting for focus, and initiating the test via the control panel. The testing process is streamlined for ease, with automated indent measurements for reliable HV values.Q: What is the measurement range of the VHT Series Tester, and what materials can it be used on?

A: The VHT Series offers a measurement range from 1 to 4500 HV, allowing testing of a wide array of materials including metals, alloys, ceramics, and other industrial samples. Its versatility makes it ideal for diverse applications in material analysis.Q: When and where can customers purchase the Vickers Hardness Tester in India?

A: Customers across India can purchase the VHT Series through authorized dealers, exporters, manufacturers, retailers, suppliers, and wholesalers. Availability covers most industrial hubs and online platforms, allowing prompt access to the product.Q: What is the process for obtaining accurate hardness measurements with this tester?

A: Prepare the sample surface, place it securely on the stage, and select the desired load on the instrument. Initiate the indentation process, and the built-in system measures the indent to calculate the hardness value according to the Vickers method.Q: How does using the VHT Series benefit manufacturers and researchers?

A: Manufacturers and researchers benefit through precise hardness determination, facilitating quality control, material selection, and performance assessments. Its extensive range and accurate results support better decision-making and product development.Q: Where can technical support and maintenance services for the VHT Series be accessed?

A: Technical support and routine maintenance are provided by the supplying dealer, manufacturer, or local service centers in India. These support services ensure optimal instrument performance and longevity.

More Products in Vicker Hardness Tester Category

Computerized Load Cell Based Digital Vickers Hardness Tester (THT-AD Series with VIDAS 2.0)

Price 1 INR / Number

Minimum Order Quantity : 1 Millimeter

Power Supply : AC220V±5% 5060Hz

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Machine Weight : 42 Kilograms (kg)

Operating Voltage : AC220V ±5%

Computerized Load Cell Based Digital Vickers Hardness Tester (THT-D Series with VIDAS 2.0)

Price 1 INR / Number

Minimum Order Quantity : 1 Millimeter

Power Supply : AC220V±5% 5060Hz

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Machine Weight : 42 Kilograms (kg)

Operating Voltage : AC220V±5%, 50/60Hz

Vickers Hardness Tester (VHT-Series with Vidas 2.0)

Price 1 INR / Number

Minimum Order Quantity : 1 Number

Power Supply : AC220V±5% 5060Hz

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Machine Weight : 42 Kilograms (kg)

Operating Voltage : AC220V±5%

Touch Screen Vickers Hardness Tester (VHT-T Series with Vidas 2.0)

Price 1 INR / Number

Minimum Order Quantity : 1 Number

Power Supply : AC220V±5% 5060Hz

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Machine Weight : 42 Kilograms (kg)

Operating Voltage : AC220V±5% 5060Hz

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry