Computerized Load Cell Based Digital Vickers Hardness Tester (THT-AD Series with VIDAS 2.0)

Computerized Load Cell Based Digital Vickers Hardness Tester (THT-AD Series with VIDAS 2.0) Specification

- Application

- Metallurgical, Plastics and Industrial Material Testing

- Specimen Size

- Max 200 x 130 mm (stage size)

- Number of Specimens

- Multiple (depends on stage size arrangement)

- Temperature

- 10°C ~ 40°C operating range

- Hardness

- Vickers (HV1~HV100)

- Display Type

- VIDAS 2.0 Software Digital Display (PC/LCD)

- Power Supply

- AC220V±5% 50-60Hz

- Mounting Type

- Table Top

- Interface Type

- USB, RS-232

- Port Size

- Standard USB/RS-232 Interface Ports

- Dimension (L*W*H)

- 585X200X630 Millimeter (mm)

- Equipment Type

- Computerized Load Cell Based Digital Vickers Hardness Tester

- Test Range

- HV1 to HV100 (Vickers Hardness)

- Automation Grade

- Fully Automatic

- Resolution

- 0.01 µm (micron) indentation measurement

- Operating Voltage

- AC220V ±5%

- Features

- Load cell based automatic application, Auto Turret, Auto Focusing, Image Analysis Data Storage, Graphical Reporting

- Accuracy

- ±1% (as per ISO 6507/ASTM E384)

- Humidity

- ≤80% RH (non-condensing)

- Response Time

- Immediate/Digital readout

- Frequency

- 50-60Hz

- Measuring Range

- 1HV to 3000HV

- Max Height

- Up to 150 mm specimen height

- Usage

- Micro/Macro Vickers Hardness Testing of metals/alloys

- Capacity

- Load Cell Capacity: 1gf-100kgf selectable

- Machine Weight

- 42 Kilograms (kg)

- Test Speed

- Standard Motorised (fully automatic) loading/unloading

- Test Width

- Up to 100 mm (throat depth)

- Test Stroke

- Up to 150 mm (vertical movement)

- Control Mode

- Microprocessor controlled, software integrated

Computerized Load Cell Based Digital Vickers Hardness Tester (THT-AD Series with VIDAS 2.0) Trade Information

- Minimum Order Quantity

- 1 Millimeter

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Millimeter Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Computerized Load Cell Based Digital Vickers Hardness Tester (THT-AD Series with VIDAS 2.0)

Features

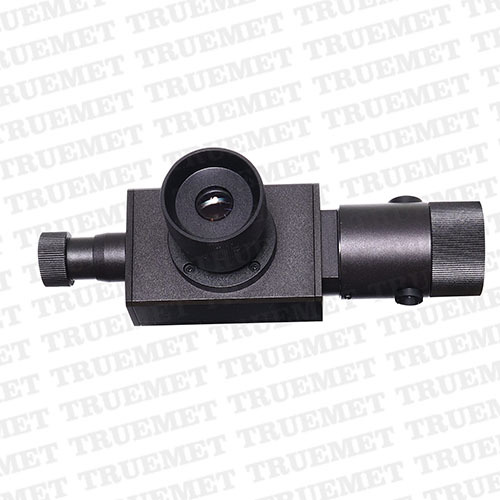

DIGITAL EYEPIECE : Equipped with 10x Digital Eyepiece to directly measure the length of the diagonal. The hardness value can be displayed directly and there is no need to enter the length of the diagonal.

ILLUMINATION SYSTEM : Halogen illumination unit gives very clear images and can be also used as a simple microscope. Halogen illumination unit enter stand by mode after a certain period of inactivity which gives it a long service life and low power consumption.

DATA OUTPUT : Equipped with built in thermal printer to take the print out the hardness result.

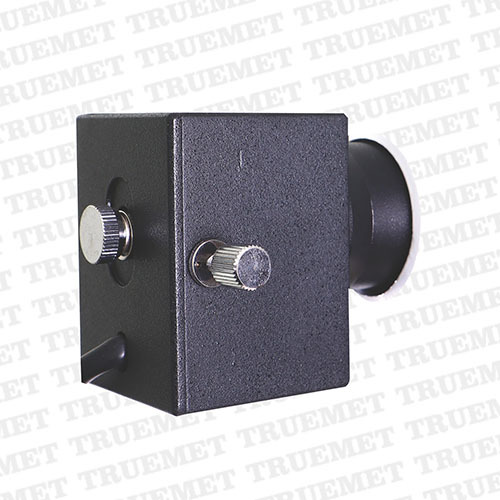

CAMERA PORT : Machine equipped with dual optical channel. 5 MP USB Camera is connected to one of the dual optical channels, other optical channel is for 10X eyepiece. Both optical channel works simultaneously.

TEST FORCE : All the test force is applied by load cell. The high quality load sensing system can do a wide-range of vickers test by one load cell.

AUTI TURRET MECHANISM : Equipped with auto turret mechanism. Auto turret perform a series of operation and measuring lens automatically comes back to central position after making indentation. The position of the indenter and the objective lens can be automatically switched using keypad.

LARGE LCD SCREEN PANEL : 75X100 mm LCD screen can visually display the hardness value, conversion hardness, test force, dwell time, upper & lower limit, max-min, and average value.

EMERGENCY SWITCH : Equipped with emergency stop switch.

Precision and Efficiency in Hardness Testing

The THT-AD Series Digital Vickers Hardness Tester deploys a computerized load cell system, providing consistently accurate results with minimal operator intervention. With auto-turret, motorized XY stage, and auto-focusing capabilities, users can speed up testing procedures and maintain high precision, even for multiple specimens. The automated calibration with certified blocks guarantees repeatable accuracy, minimizing human error and sample variability.

Advanced Analysis with VIDAS 2.0 Software

Equipped with VIDAS 2.0, this tester offers comprehensive data acquisition, statistical evaluation, and XY hardness mapping functions directly from your PC. Graphical reporting, image analysis, and secure data storage enhance the analysis process, while the digital display streamlines reading outcomes. The software supports both Vickers and (optionally) Knoop hardness scales, making it adaptable to a variety of testing needs.

Versatility and User-Friendly Design

Designed for diverse applications, this instrument is well suited for metallurgical, plastics, and industrial material testing. Its motorized stage accommodates specimens up to 200 x 130 mm and heights up to 150 mm, while various load ranges (1gf-100kgf) allow both micro and macro testing. The robust yet compact construction and intuitive software integration make it ideal for industrial labs, research, or educational environments.

FAQs of Computerized Load Cell Based Digital Vickers Hardness Tester (THT-AD Series with VIDAS 2.0):

Q: How does the VIDAS 2.0 software enhance the hardness testing process?

A: VIDAS 2.0 streamlines data acquisition, enables advanced statistical analysis, and facilitates XY hardness mapping. It also offers image analysis, graphical reporting, and seamless data storage, resulting in comprehensive and accessible test results.Q: What is the benefit of computerized load cell-based hardness measurement?

A: A load cell ensures accurate, repeatable application of force, reducing variability and operator error. The computerized system further automates the process, providing precise control for both micro and macro Vickers testing.Q: When is the automated calibration function utilized, and what advantages does it provide?

A: Automated calibration is used before starting hardness tests or when switching specimen types. It ensures measurement accuracy by using certified calibration blocks, maintaining compliance with ISO 6507 and ASTM E384 standards.Q: Where can this hardness tester be effectively used?

A: The THT-AD Series is suitable for metallurgical laboratories, quality assurance departments, research institutions, plastics and materials testing environments, or any location requiring precise hardness measurement.Q: What is the process for testing a specimen with this device?

A: The process involves placing the specimen on the motorized stage, selecting the required load and test parameters via VIDAS 2.0, and initiating the test. The system will auto-focus, position, apply load, measure, and record the results automatically.Q: How does the adjustable stage benefit users during testing?

A: The motorized XY adjustable stage allows for precise positioning and sequential measurement of multiple points or specimens, facilitating efficient batch testing and mapping hardness gradients across large samples.

More Products in Vicker Hardness Tester Category

Computer Controlled Load Cell Based Vickers Hardness Tester (THT-A Series with VIDAS 4.0)

Minimum Order Quantity : 1 Millimeter

Machine Weight : 42 Kilograms (kg)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Power Supply : AC220V±5% 5060Hz

Automation Grade : Fully Automatic

Test Range : 5HV – 2900HV

Computerized Digital Touch Screen Vickers Hardness Tester (VHT-DT Series with VIDAS 2.0)

Minimum Order Quantity : 1 Number

Machine Weight : 42 Kilograms (kg)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Power Supply : AC220V±5% 5060Hz

Automation Grade : Semiautomatic with Automatic Turret

Test Range : 5g 3kgf (Vickers Load Range)

Vickers Hardness Tester (VHT-A Series with Vidas 2.0)

Minimum Order Quantity : 1 Number

Machine Weight : 42 Kilograms (kg)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Power Supply : AC220V±5% 5060Hz

Automation Grade : Automatic

Test Range : HV5 to HV1000

Computerized Load Cell Based Vickers Hardness Tester (THT-A Series with VIDAS 2.0)

Minimum Order Quantity : 1 Millimeter

Machine Weight : 42 Kilograms (kg)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Power Supply : AC220V±5% 5060Hz

Automation Grade : Fully Automatic

Test Range : 1 HV ~ 3000 HV

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry