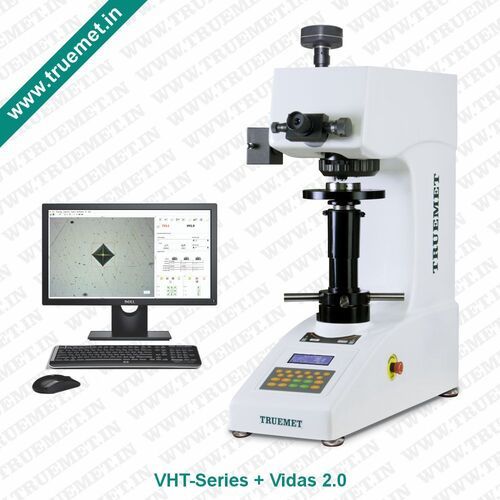

Computerized Load Cell Based Vickers Hardness Tester (THT-A Series with VIDAS 2.0)

Computerized Load Cell Based Vickers Hardness Tester (THT-A Series with VIDAS 2.0) Specification

- Features

- Automatic Turret, Auto Focus, Data Storage, Data Export, User Calibration

- Automation Grade

- Fully Automatic

- Frequency

- 50-60Hz

- Operating Voltage

- AC220V

- Response Time

- <1 Sec

- Test Range

- 1 HV ~ 3000 HV

- Measuring Range

- 1 HV – 3000 HV

- Number of Specimens

- Multiple (software defined)

- Accuracy

- ≤ ±1%

- Equipment Type

- Computerized Load Cell Based Vickers Hardness Tester

- Port Size

- Standard USB and RS232

- Hardness

- Vickers (HV1 to HV1000)

- Dimension (L*W*H)

- 585X200X630 Millimeter (mm)

- Mounting Type

- Benchtop/Lab

- Temperature

- 15°C to 40°C

- Interface Type

- USB, RS232

- Power Supply

- AC220V±5% 50-60Hz

- Application

- Micro-hardness and Macro-hardness testing for metals and alloys

- Resolution

- 0.1 HV

- Humidity

- 10% - 90% non-condensing

- Specimen Size

- Up to 200 mm x 175 mm

- Display Type

- LCD Touch Screen and VIDAS 2.0 Software

- Max Height

- 175 mm

- Usage

- Laboratory/Industrial

- Capacity

- Load 1gf to 1000gf

- Machine Weight

- 42 Kilograms (kg)

- Test Speed

- Adjustable, up to 1 mm/sec

- Test Width

- 100 mm (max)

- Test Stroke

- Up to 80 mm

- Control Mode

- Computerized / Load Cell Control

Computerized Load Cell Based Vickers Hardness Tester (THT-A Series with VIDAS 2.0) Trade Information

- Minimum Order Quantity

- 1 Millimeter

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Millimeter Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Computerized Load Cell Based Vickers Hardness Tester (THT-A Series with VIDAS 2.0)

Features

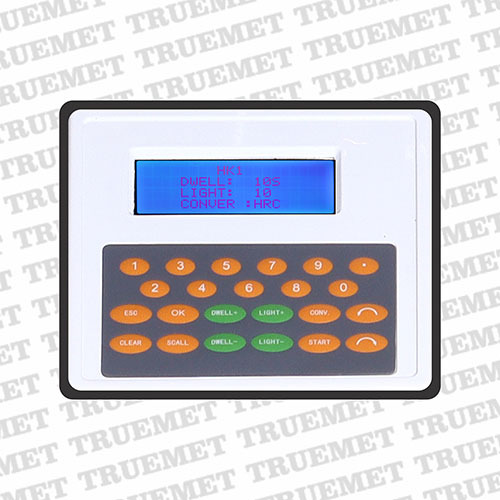

MANUAL EYEPIECE : Equipped with 10x Manual Eyepiece to measure the length of diagonal. The hardness value can be displayed directly on LCD screen by entering the indentation diagonal length.

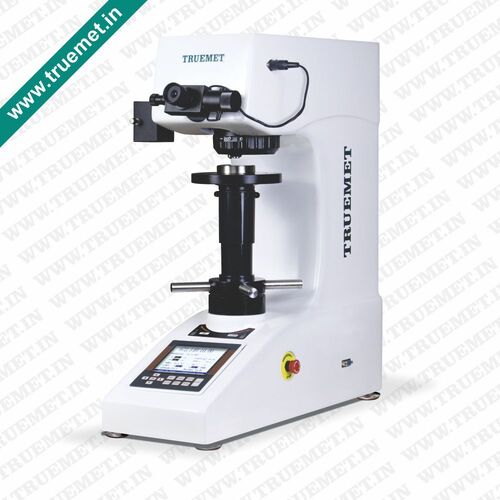

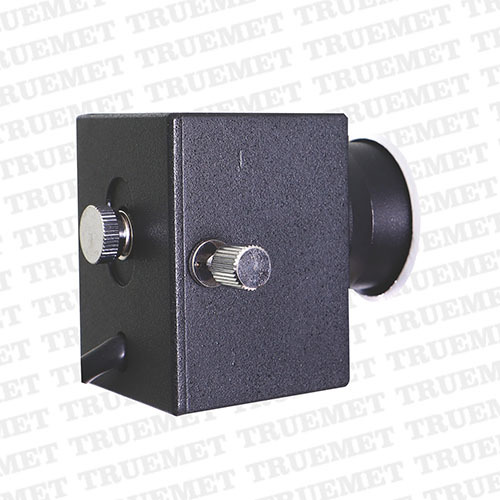

CAMERA PORT : Machine equipped with dual optical channel. 5 MP USB Camera is connected to one of the dual optical channels, other optical channel is for 10X eyepiece. Both optical channel works simultaneously.

ILLUMINATION SYSTEM : Halogen illumination unit gives very clear images and can be also used as a simple microscope. Halogen illumination unit enter stand by mode after a certain period of inactivity which gives it a long service life and low power consumption.

TEST FORCE : All the test force is applied by load cell. The high quality load sensing system can do a wide-range of vickers test by one load cell.

LCD SCREEN : 80X25mm LCD Screen can visually display the hardness value, conversion hardness, test force and dwell time.

AUTO TURRET MECHANISM : Equipped with auto turret mechanism. Auto turret perform a series of operation and measuring lens automatically comes back to central position after making indentation. The position of the indenter and the objective lens can be automatically switched using keypad.

EMERGENCY SWITCH : Equipped with emergency stop switch.

Advanced Imaging and Measurement

This Vickers hardness tester incorporates a high-resolution CCD camera, offering clear, detailed impressions at magnifications up to 1000x. The advanced objective system, along with automatic focus and turret capabilities, facilitates highly accurate and repeatable measurements.

Seamless Data Handling and Connectivity

VIDAS 2.0 software manages automatic data acquisition, analysis, and report generation. Data can be securely stored internally or transferred via USB and RS232 ports, with support for direct printing. The system also supports multi-language operation for global usability.

Effortless Operation and Safety

With a fully automatic, computerized control interface, users benefit from plug & play installation, adjustable test speed, and straightforward calibration processeseither manual or automatic. Built-in safety features include overload protection and an emergency stop for operator and equipment security.

FAQs of Computerized Load Cell Based Vickers Hardness Tester (THT-A Series with VIDAS 2.0):

Q: How does the VIDAS 2.0 software enhance the efficiency of the Vickers Hardness Tester?

A: VIDAS 2.0 software automates the data acquisition and report generation processes, reducing manual data entry and analysis errors. It provides a user-friendly interface, supports multi-language operation, and enables easy data storage, export, and printing, making laboratory or industrial workflows more streamlined and efficient.Q: What specimen sizes and hardness ranges can be tested with this equipment?

A: This hardness tester accommodates specimens up to 200 mm x 175 mm with a maximum test height of 175 mm. It measures Vickers hardness within a broad range of 1 HV to 3000 HV, making it suitable for various metals and alloys in both micro-hardness and macro-hardness applications.Q: When is the automatic calibration feature recommended over manual calibration?

A: Automatic calibration is ideal for routine testing or when performing frequent measurements, as it saves time and ensures consistent accuracy. Manual calibration may be preferred in specialized testing scenarios or when verifying accuracy against certified reference materials.Q: Where can this Vickers Hardness Tester be installed, and what are its space requirements?

A: Designed for benchtop or laboratory installation, the testers compact dimensions (585 x 200 x 630 mm) and desktop footprint allow it to fit comfortably in most laboratory or industrial environments with access to a standard AC220V power supply.Q: What is the process for conducting a hardness test using this machine?

A: To perform a test, place the specimen on the stage, select the required test parameters through the touchscreen or VIDAS 2.0 software, and initiate the test. The system automatically controls load application, impression measurement with the CCD camera, and records results. Reports can be generated and exported directly.Q: In what ways does this tester ensure operator and sample safety during use?

A: The system includes multiple safety features such as overload protection and an emergency stop button. These safeguards protect both operator and equipment against unexpected errors or hazardous conditions during operation.Q: What benefits are gained from using a computerized, load cell-based Vickers Hardness Tester in an industrial environment?

A: Users benefit from high precision ( 1% accuracy), rapid response time, automation, and efficient data workflows. The systems robust build, easy calibration, extensive measuring range, and advanced reporting capabilities enhance productivity, reduce downtime, and improve the reliability of test outcomes.

More Products in Vicker Hardness Tester Category

Computerized Load Cell Based Vickers Hardness Tester (THT-Series with VIDAS 2.0)

Minimum Order Quantity : 1 Millimeter

Test Stroke : 0–50 mm

Response Time : <2 sec

Test Range : 5–3000 HV

Frequency : 5060 Hz

Operating Voltage : AC 220V ±5%

Load Cell Based Digital Vickers Hardness Tester (THT-AD Series)

Minimum Order Quantity : 1 Number

Test Stroke : Up to 100 mm

Response Time : Instantaneous, <1s

Test Range : 53000 HV (Vickers Hardness)

Frequency : 5060 Hz

Operating Voltage : AC220V

Computer Controlled Load Cell Based Vickers Hardness Tester (THT-A Series with VIDAS 4.0)

Minimum Order Quantity : 1 Millimeter

Test Stroke : Max 90 mm

Response Time : ≤3 seconds per indent

Test Range : 5HV – 2900HV

Frequency : 5060Hz

Operating Voltage : AC220V ±5% 5060Hz

Computerized Digital Touch Screen Vickers Hardness Tester (VHT-DT Series with VIDAS 2.0)

Minimum Order Quantity : 1 Number

Test Stroke : 0100 mm (Motorized Z Axis)

Response Time : <1 Second

Test Range : 5g 3kgf (Vickers Load Range)

Frequency : 5060 Hz

Operating Voltage : AC220V ±5% 5060Hz

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry