Digital Touch Screen Micro Vickers Hardness Tester (HT-1000ADT)

Digital Touch Screen Micro Vickers Hardness Tester (HT-1000ADT) Specification

- Hardness

- Micro Vickers (10 gf to 1000 gf)

- Display Type

- 7-inch color touch screen

- Response Time

- Instantaneous digital readout

- Power Supply

- AC220V±5% 50-60Hz

- Test Range

- 1HV – 2967HV

- Measuring Range

- 1HV~2967HV

- Mounting Type

- Benchtop

- Interface Type

- USB, RS232 data output

- Application

- Metallurgical samples, thin and small precision parts

- Port Size

- Standard Vickers indenter size

- Specimen Size

- Max sample height: 85 mm; Sample depth: 120 mm

- Dimension (L*W*H)

- 530X200X530 Millimeter (mm)

- Features

- Digital touch screen, auto turret, precision loading system

- Operating Voltage

- AC220V±5%

- Frequency

- 50-60Hz

- Automation Grade

- Semi-automatic

- Max Height

- 85 mm (max specimen height)

- Temperature

- Operating: 10°C - 35°C

- Number of Specimens

- Multiple (with specimen holder)

- Accuracy

- Conforms to ISO 6507, ASTM E384

- Equipment Type

- Digital Micro Vickers Hardness Tester

- Resolution

- 0.01 μm

- Humidity

- ≤85% RH (non-condensing)

- Usage

- Microhardness testing of metals, ceramics, composites

- Capacity

- Indenter capacity to 1000 gf

- Machine Weight

- 35 Kilograms (kg)

- Test Speed

- Automatic (speed control depends on load and cycle settings)

- Test Width

- Up to 100 mm (sample dependent)

- Test Stroke

- Adjustable, up to 100 mm

- Control Mode

- Touch screen digital control

Digital Touch Screen Micro Vickers Hardness Tester (HT-1000ADT) Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Digital Touch Screen Micro Vickers Hardness Tester (HT-1000ADT)

FeaturesDIGITAL EYEPIECE :Equipped with 10x Digital Eyepiece to directly measure the length of the diagonal. The hardness value can be displayed directly and there is no need to enter the length of the diagonal.

CAMERA PORT :Machine equipped with dual optical channel, one optical channel for 10X eyepiece and another optical channel is for camera by which machine can be upgraded into computerized model. Both optical channel works simultaneously.

ILLUMINATION SYSTEM :Halogen illumination unit with adjustable intensity gives very clear images and can be also used as a simple microscope. Halogen illumination unit enter stand by mode after a certain period of inactivity which gives it a long service life and low power consumption.

TEST FORCE :Wide range of test force (10gm to 1000gm) can be selected with external force selection knob. The test force is automatically displayed on the 7 inch LCD touch display.

DATA OUTPUT :Equipped with built is thermal printer to take the print out the hardness result USB port is also available to get the data in pendrive.

AUTO TURRET MECHANISM :Equipped with auto turret mechanism. Auto turret perform a series of operation and measuring lens automatically comes back to central position after making indentation. The position of the indenter and the objective lens can be automatically switched using touch panel.

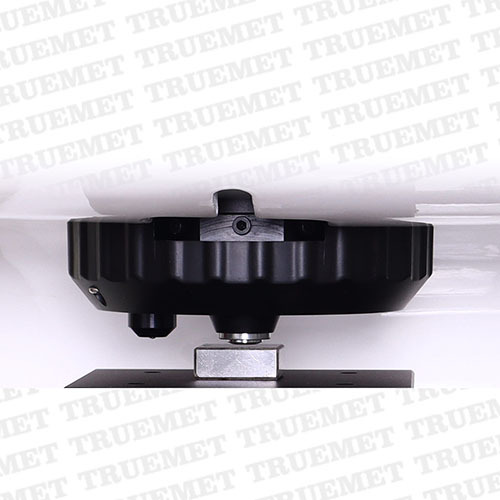

Z-AXIS LIFTING SYSTEM :Side-Ways lifting system makes the z-axis movement more stable and accurate.

LCD TOUCH SCREEN PANEL :7 Inch LCD touch screen can visually display the hardness value, hardness conversion (4 conversion scales can be displayed at the same time), test force, dwell time, statistical data, upper & lower limit and brightness of optical system.

EMERGENCY SWITCH :Equipped with emergency stop switch.

Advanced Measurement Capabilities

The HT-1000ADT is engineered for highly accurate microhardness testing, conforming strictly to ISO 6507 and ASTM E384 standards. It accommodates a broad spectrum of loads (10 gf to 1000 gf) and offers optional objectives for increased magnification. Its automatic speed control and adjustable dwell time ensure comprehensive test adaptability, ideal for metallurgical labs and electronics industries working with small and precise specimens.

User-Friendly Digital Interface

Seamlessly operated via a 7-inch color touch screen, the HT-1000ADT simplifies hardness testing. The multilingual software supports built-in hardness calculations, while an automatic turret enhances workflow efficiency by switching objectives hands-free. Real-time digital readout and data storage features promote streamlined testing procedures, optimal for busy laboratory settings.

Precision and Safety Combined

Equipped with a precision micrometer XY test table and high-quality diamond indenter, the HT-1000ADT ensures consistent, reliable results. Safety features such as overload and misoperation protection safeguard both user and equipment. Furthermore, the built-in calibration (manual and automatic) allows ongoing accuracy verification, making this an ideal choice for quality assurance processes.

FAQs of Digital Touch Screen Micro Vickers Hardness Tester (HT-1000ADT):

Q: How does the Digital Touch Screen Micro Vickers Hardness Tester (HT-1000ADT) perform hardness testing?

A: This tester uses a Vickers diamond indenter to apply controlled loads (from 10 gf to 1000 gf) on the specimen. After indentation, the high-resolution optical system and digital touch screen allow you to measure the diagonals of the impression and automatically calculate the microhardness value, ensuring precise and repeatable results.Q: What types of specimens can be tested with this equipment?

A: The HT-1000ADT is suitable for testing a wide range of materials, including metallurgical samples, thin films, small precision parts, ceramics, and composites. With a maximum specimen height of 85 mm and a depth of up to 120 mm, it accommodates multiple sample types using its specimen holder.Q: When should I use automatic versus manual calibration?

A: Automatic calibration is recommended for routine testing to ensure ongoing accuracy without manual intervention. Manual calibration is useful when establishing initial baseline settings or to comply with stricter laboratory and compliance procedures, providing flexibility as needed.Q: Where can the stored data be accessed or exported?

A: Test data (up to 100 results) are stored within the device and can be quickly accessed on the touch screen. For external analysis or record-keeping, results can be exported via USB or RS232 interfaces to a PC for further processing or archiving.Q: What is the process for adjusting test loads and dwell time?

A: Test loads and dwell times are set digitally through the touch screen interface. Choose from eight standard loads (10 gf to 1000 gf) and adjust dwell times between 1 and 60 seconds, allowing full adaptation to various materials and testing standards.Q: How does the HT-1000ADT enhance laboratory efficiency and user convenience?

A: Features like the automatic turret, intuitive multilingual touch screen, instant digital readout, automated speed control, and adjustable LED lighting streamline the sample testing process. Built-in safety mechanisms further minimize user error while promoting equipment longevity.Q: What are the main benefits of using this Micro Vickers Hardness Tester?

A: Key advantages include high test accuracy, conformity to international standards, rapid results, flexible specimen handling, and robust data management. The equipments comprehensive safety and automation features make it especially beneficial for research labs, quality control, and precision manufacturing.

More Products in Micro Vicker Hardness Tester Category

Auto Turret Micro Vickers Hardness Tester (HT-1000A)

Minimum Order Quantity : 1 Number

Application : Metallographic Laboratory, Steel and Alloy Testing

Machine Weight : 35 Kilograms (kg)

Equipment Type : Micro Vickers Hardness Tester

Resolution : 0.01 HV

Humidity : <80% RH

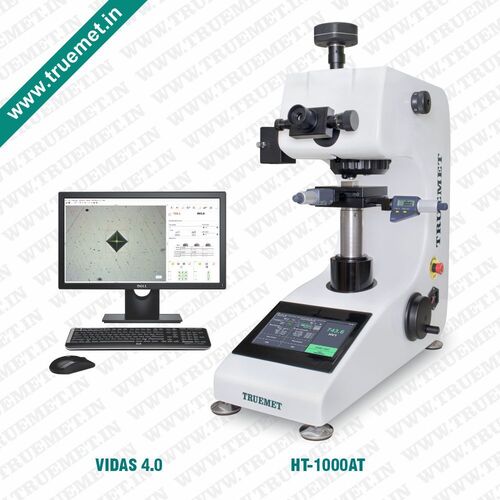

Computer Controlled Automatic Touch Screen Micro Vickers Hardness Tester (HT-1000AT with Vidas 4.0)

Minimum Order Quantity : 1 Number

Application : Metallography, material testing, scientific research, quality control

Machine Weight : 35 Kilograms (kg)

Equipment Type : Micro Vickers Hardness Tester

Resolution : 0.001 HV

Humidity : ≤85% RH (noncondensing)

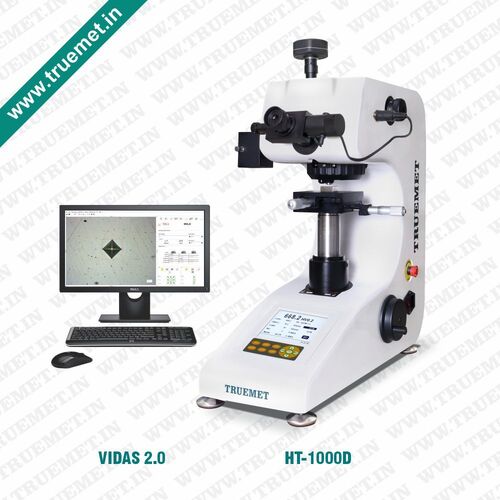

Computerized Digital Micro Vickers Hardness Tester (HT-1000D with Vidas 2.0)

Minimum Order Quantity : 1 Number

Application : Microhardness testing for metals, alloys, ceramics, and composites

Machine Weight : 35 Kilograms (kg)

Equipment Type : Computerized Digital Micro Vickers Hardness Tester

Resolution : 0.01 µm (micron)

Humidity : <90% RH

Micro Vickers Hardness Tester (HT-1000)

Minimum Order Quantity : 1 Number

Application : Micro hardness measurement of metals and alloy materials, research labs, quality control

Machine Weight : 35 Kilograms (kg)

Equipment Type : Micro Vickers Hardness Tester

Resolution : 0.025 μm

Humidity : ≤85% RH

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry