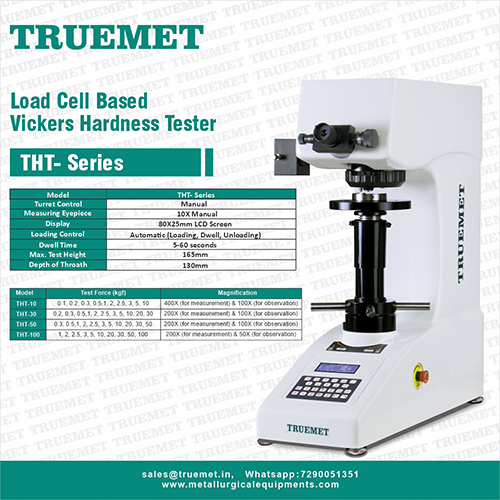

Load Cell Based Vickers Hardness Tester (THT-Series)

Load Cell Based Vickers Hardness Tester (THT-Series) Specification

- Hardness

- Vickers scale

- Frequency

- 50-60 Hz

- Automation Grade

- Semi-Automatic

- Application

- Vickers Hardness Testing of Metals

- Mounting Type

- Benchtop

- Dimension (L*W*H)

- 585X200X630 Millimeter (mm)

- Features

- Load cell based force application, automatic indentation, data storage

- Number of Specimens

- Multiple

- Temperature

- 5°C-40°C

- Measuring Range

- HV0.01-HV5

- Response Time

- ≤2 seconds

- Operating Voltage

- AC220V

- Port Size

- Ø6 mm

- Humidity

- ≤90% RH

- Voltage

- AC220 Volt (v)

- Power Supply

- AC220V±5% 50-60Hz

- Display Type

- Digital Touchscreen Display

- Accuracy

- ±1% of displayed value

- Test Range

- 5gf-5kgf

- Resolution

- 0.01 HV

- Gas Pressure

- 0.1-0.7 MPa

- Interface Type

- USB/RS232

- Equipment Type

- Load Cell Based Vickers Hardness Tester (THT-Series)

- Specimen Size

- Standard/Custom

- Max Height

- 630 mm

- Usage

- Material hardness measurement

- Capacity

- Up to 5kgf

- Machine Weight

- 42 Kilograms (kg)

- Test Speed

- 0.01-0.99 mm/s

- Test Width

- 200 mm

- Test Stroke

- 0-50 mm

- Control Mode

- Automatic/Manual

Load Cell Based Vickers Hardness Tester (THT-Series) Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Load Cell Based Vickers Hardness Tester (THT-Series)

Features

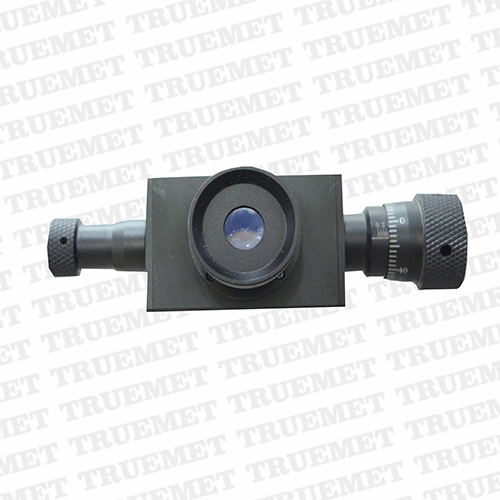

MANUAL EYEPIECE :Equipped with 10x Manual Eyepiece to measure the length of diagonal. The hardness value can be displayed directly on LCD screen by entering the indentation diagonal length.

ILLUMINATION SYSTEM :Halogen illumination unit gives very clear images and can be also used as a simple microscope. Halogen illumination unit enter stand by mode after a certain period of inactivity which gives it a long service life and low power consumption.

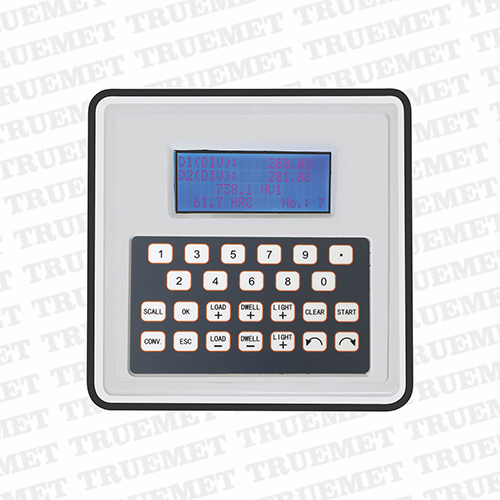

LCD SCREEN :80X25mm LCD Screen can visually display the hardness value, conversion hardness, test force and dwell time.

CAMERA PORT :Machine equipped with dual optical channel, one optical channel for 10X eyepiece and another optical channel is for camera by which machine can be upgraded into computerized model. Both optical channel works simultaneously.

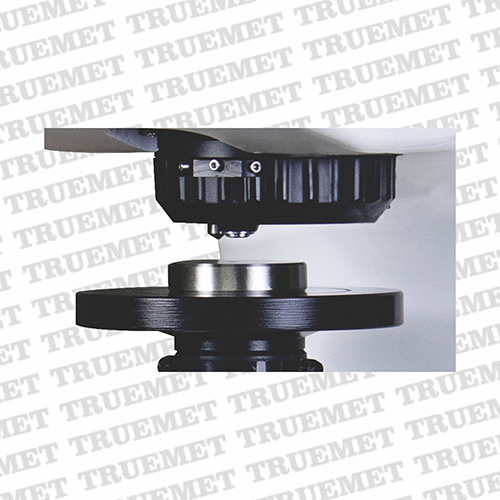

TEST FORCE :All the test force is applied by load cell. The high quality load sensing system can do a wide-range of vickers test by one load cell.

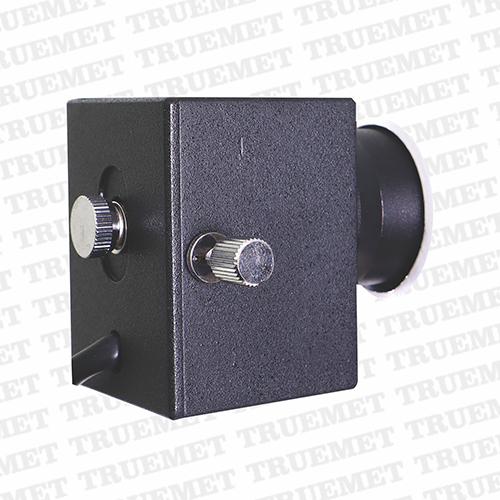

TURRET MECHANISM :Equipped with manual turret mechanism. The position of the indentor and objective lens can be switched manually.

EMERGENCY SWITCH :Equipped with emergency stop switch.

Advanced Digital Imaging and Precision Control

The THT-Series harnesses high-precision digital imaging for reliable Vickers indentation measurements, combined with a digital fine adjustment mechanism. This facilitates clear, real-time viewing and enhanced accuracy through selectable objective lenses and LED illumination. Automatic and manual calibration options ensure consistent performance, while touch controls streamline operation.

Robust Construction and User-Focused Design

Designed for demanding work environments, the tester boasts a sturdy industrial grey frame and benchtop mounting. Its X-Y stage allows both manual and automated movement, accommodating multiple specimens of various sizes. The systems responsive emergency stop, overload protection, and low power consumption (<60W) help safeguard users and specimens alike.

Seamless Data Management and Automation

Easily export measurement results via USB or RS232 ports for enhanced traceability and reporting. Compatible with Windows OS software, the device supports comprehensive data storage and analysis. Operators can select between automatic or manual control modes, tailored to both routine testing and specialized applications in metal hardness assessment.

FAQs of Load Cell Based Vickers Hardness Tester (THT-Series):

Q: How does the Load Cell Based Vickers Hardness Tester ensure measurement accuracy?

A: This tester utilizes a load cell-based force application system with a diamond pyramidal indenter, providing high precision and uniform force application. Automated or manual calibration maintains accurate results, which are verified with a digital imaging system capable of 0.01 HV resolution and 1% accuracy.Q: What is the process for exporting data from the THT-Series tester?

A: Measurement data can be quickly exported using the built-in USB or RS232 interfaces. This facilitates seamless integration with Windows-based software, allowing fast data transfer for records, analyses, or quality reports.Q: When is it necessary to recalibrate the hardness tester?

A: Recalibration should be performed periodically, after significant changes in usage, or when prompted by the devices software following a deviation from expected results. The machine provides both automatic and manual calibration features for user convenience.Q: Where can the THT-Series Vickers Hardness Tester be installed?

A: This benchtop device is suitable for laboratories, manufacturing quality control rooms, research institutions, and educational establishments. Its compact yet robust design fits standard laboratory benches or workstations.Q: What benefits do LED illumination and digital imaging offer during testing?

A: LED illumination ensures clear observation of indentation marks, while the high-precision digital imaging system enables accurate, repeatable hardness measurements by minimizing operator error and allowing for precise documentation.Q: How is specimen handling managed with different sample sizes?

A: The tester features both manual and automatic X-Y stage movement, enabling precise positioning of multiple specimens, whether standard or custom-sized, within its spacious test area (up to 200 mm width and 0-50 mm stroke).

More Products in Vicker Hardness Tester Category

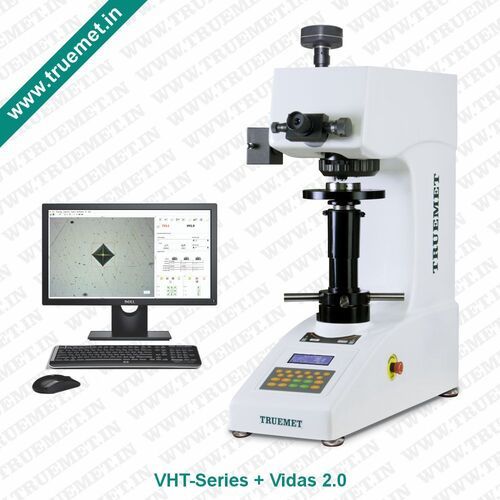

Computerized Load Cell Based Vickers Hardness Tester (THT-Series with VIDAS 2.0)

Minimum Order Quantity : 1 Millimeter

Machine Weight : 42 Kilograms (kg)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Power Supply : AC220V±5% 5060Hz

Control Mode : Computerized (VIDAS 2.0 software)

Operating Voltage : AC 220V ±5%

Computerized Digital Touch Screen Vickers Hardness Tester (VHT-DT Series with VIDAS 2.0)

Minimum Order Quantity : 1 Number

Machine Weight : 42 Kilograms (kg)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Power Supply : AC220V±5% 5060Hz

Control Mode : Computerized Digital Touch Screen with VIDAS 2.0 Software

Operating Voltage : AC220V ±5% 5060Hz

Touch Screen Vickers Hardness Tester (VHT-AT Series with Vidas 2.0)

Minimum Order Quantity : 1 Number

Machine Weight : 42 Kilograms (kg)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Power Supply : AC220V±5% 5060Hz

Control Mode : Touch Screen / Automatic

Operating Voltage : AC220V

Digital Vickers Hardness Tester (VHT-AD Series)

Minimum Order Quantity : 1 Number

Machine Weight : 35 Kilograms (kg)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Power Supply : AC220V±5% 5060Hz

Control Mode : Automatic with Digital Operation

Operating Voltage : 220V

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry