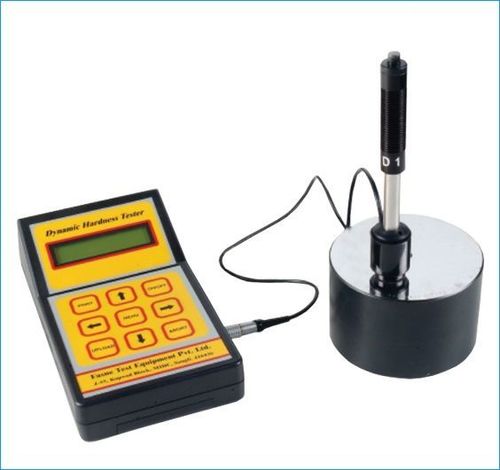

Portable Hardness Tester-IM

Portable Hardness Tester-IM Specification

- Features

- Portable, Digital Display, Data Storage

- Specimen Size

- Minimum 70 mm width

- Dimension (L*W*H)

- 125X70X26 Millimeter (mm)

- Equipment Type

- Portable Hardness Tester

- Interface Type

- USB/RS232

- Mounting Type

- Handheld

- Frequency

- Standard

- Power Supply

- 1.5 VDC X 2Nos.

- Display Type

- LCD

- Temperature

- 0-40°C

- Application

- Hardness testing of metals

- Humidity

- ≤ 90% RH

- Accuracy

- ±4 HL (0.5% FS)

- Response Time

- Instantaneous

- Operating Voltage

- 3V (1.5V x 2 AA batteries)

- Port Size

- Standard

- Test Range

- 170~960 HL

- Number of Specimens

- 1

- Hardness

- Leeb Hardness HL, HRC, HB, HV, HRB, HRA, HS

- Max Height

- 125 mm

- Measuring Range

- 170-960 HL (Leeb Hardness)

- Resolution

- 1 HL

- Automation Grade

- Manual/Automatic

- Usage

- Metal hardness measurement

- Machine Weight

- 350 Gram (g)

- Test Speed

- Standard (As per device capability)

- Test Width

- Up to 70 mm

- Test Stroke

- 26 mm

- Control Mode

- Manual/Automatic

Portable Hardness Tester-IM Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Portable Hardness Tester-IM

Application

Permanently assembled and installed parts

large and heavy components in forging, tool room, foundries & Heat Treatment units.

measurement of hardness in confined spaces

Material identification of metallic material

surface hardened components

Features

Large LCD Display(30X52 dot matrix) showing hardness value, Direction of impact device, hardness scale, material, test Time for average and battary icon

Direct Display of hardness in HV, HB, HRC, HRB, HRA and HS Scales.

7 types of impact devices can be attached for special application and need not to be recalibrated when changing them.

the machine identify the type of impact device automatically

Upto 600 groups (impact times:32 1) of data can be stored in internal memory of the machine.

Upper and lower limit of hardness can be preset. when the tested value exceeds the limits, alarm buzz automatically

Back light on/off facility is given by pressing key to make machine converient for use in poor light.

User Calibration function.

By Using Software, data can be transfered and saved in pc for future use.

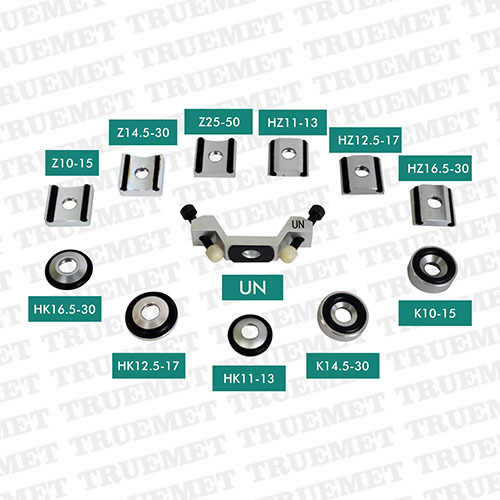

Different types of impact devices and there uses

Impact Device D :Universal Standard Impact device use for testing majority of metallic components

Impact device DL:Testing of slender, narrow groove and extermely confirmed spaces.

Impact Device DC:Extremely short impact device for very confirmed space such as holes, cylinders etc.

Impact Device DL+15 :Slim front section with coil set back used in grooves, recessed surface like T-Slot

Impact Device C :low impact energy device used for testing case hardened, coating and thin walledcomponents.

Impact Device G :Suitable on heavy component such as rough casting and forgings in brinell scale only.

Impact Device E :Suitable for testing super high hardness maerial.

Rugged and Portable Design

Constructed with an ABS housing and a steel probe, the Portable Hardness Tester-IM provides durable performance in a lightweight 350g frame. The compact dimensions and ergonomic design make it perfect for handheld, on-site testing, even in challenging conditions.

Advanced Features for Reliable Testing

This device offers both manual and automatic control modes, memory storage for 100 results, and a backlit LCD display for clear viewing. Calibration can be conducted automatically or manually, ensuring flexible and precise hardness measurement for various metals.

User-Friendly Operation & Versatility

Supporting multiple languages and a broad Leeb Hardness scale (HL, HRC, HB, HV, etc.), the tester meets diverse industry needs. The easy interface with USB/RS232 connectivity, instantaneous response, and compatibility with metal specimens at least 70 mm wide enhance its usability.

FAQs of Portable Hardness Tester-IM:

Q: How do I operate the Portable Hardness Tester-IM for metal hardness measurement?

A: Begin by powering on the device using two 1.5V AA batteries, select your desired language, and choose between manual or automatic control. Place the steel probe on the metal specimen (minimum 70 mm width) and follow the display instructions. Results are delivered instantaneously with a clear backlit LCD readout.Q: What materials can be tested using this hardness tester?

A: The device is designed for hardness testing of metals, supporting various scales such as Leeb Hardness (HL), HRC, HB, HV, HRB, HRA, and HS. It is suitable for manufacturers, suppliers, and metalworkers needing to assess the hardness of metallic components.Q: Where can I use the Portable Hardness Tester-IM?

A: This tester is ideal for on-site, factory, and quality control environments. With an operating temperature of 0-40C and humidity up to 90% RH, it handles most workshop and field conditions commonly found in industrial settings.Q: What is the memory capacity and how can I access stored data?

A: The tester can store up to 100 groups of hardness results. Data can be accessed and exported via its standard USB/RS232 interface, facilitating easy record-keeping and further analysis on a connected computer.Q: How is calibration performed on the tester?

A: Calibration can be executed either automatically or manually according to user preference. The process is straightforwardfollow the on-screen instructions to ensure accuracy before each testing session or after prolonged use.Q: What are the main benefits of using this portable hardness tester?

A: Key advantages include swift, accurate hardness readings, portability for field testing, robust durability, simple operation, multi-language support, extensive result storage, and compatibility with various metal hardness scales, supporting efficient quality control.Q: When should I replace the batteries, and what is the expected battery life?

A: Replace the batteries when the display indicates low power or when the device response diminishes. Under normal conditions, two 1.5V AA batteries provide up to 100 hours of continuous testing, ensuring long usage between battery changes.

More Products in Portable Hardness Tester Category

Portable Hardness Tester-II

Price 1 INR / Number

Minimum Order Quantity : 1 Number

Application : Metal hardness testing

Machine Weight : 0.6 Kilograms (kg)

Power Supply : 9V/500mA

Poldi Hardness Tester

Price Range 2800.00 - 3600.00 INR

Minimum Order Quantity : 1 Box

Application : Industrial

Machine Weight : 535 Kilograms (kg)

Power Supply : Not required (manual operation)

Portable Hardness Tester-I

Price 1 INR / Number

Minimum Order Quantity : 1 Number

Application : Metal Hardness Measurement

Machine Weight : 0.3 Kilograms (kg)

Power Supply : 1.5 VDC X 2Nos.

Dynamic Hardness Tester

Price Range 25000.00 - 150000.00 INR

Minimum Order Quantity : 1 , , Unit

Application : Industrial

Machine Weight : 0.2300.500 Kilograms (kg)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry