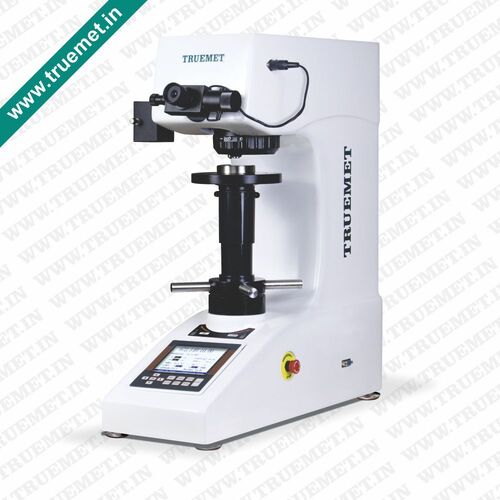

Touch Screen Vickers Hardness Tester (VHT-AT Series with VIDAS 4.0)

Touch Screen Vickers Hardness Tester (VHT-AT Series with VIDAS 4.0) Specification

- Specimen Size

- Max thickness: 130 mm, max width: 135 mm

- Humidity

- ≤85% RH for operation

- Hardness

- Vickers (HV)

- Application

- Metallurgical laboratory, quality control, research, engineering

- Interface Type

- USB, RS232, HDMI

- Response Time

- <2 seconds per measurement

- Test Range

- 1HV~2967HV (Vickers Hardness Value)

- Frequency

- 50-60Hz

- Power Supply

- AC220V±5% 50-60Hz

- Gas Pressure

- N/A (not applicable)

- Accuracy

- ±1.0%

- Automation Grade

- Automatic

- Display Type

- 7 touch screen color LCD

- Port Size

- Standard USB/RS232 and HDMI ports

- Max Height

- 130 mm (specimen)

- Equipment Type

- Touch Screen Vickers Hardness Tester, Model VHT-AT Series

- Dimension (L*W*H)

- 585X200X630 Millimeter (mm)

- Number of Specimens

- Single specimen per cycle

- Temperature

- 10°C ~ 30°C (operational)

- Mounting Type

- Benchtop/laboratory tabletop

- Features

- Motorized turret, auto-focusing, touch screen operation, integrated camera, data storage, motorized X-Y stage

- Operating Voltage

- AC220V±5% 50-60Hz

- Measuring Range

- 1–2967 HV

- Resolution

- 0.01 μm

- Usage

- Vickers microhardness measurement and analysis

- Capacity

- To test various metals and alloys, load selection: 10g to 1kg

- Machine Weight

- 42 Kilograms (kg)

- Test Speed

- Configurable, motorized (precise control via VIDAS 4.0)

- Test Width

- Up to 135 mm

- Test Stroke

- 0~100 mm

- Control Mode

- Touch Screen & Automatic (VIDAS 4.0)

Touch Screen Vickers Hardness Tester (VHT-AT Series with VIDAS 4.0) Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Touch Screen Vickers Hardness Tester (VHT-AT Series with VIDAS 4.0)

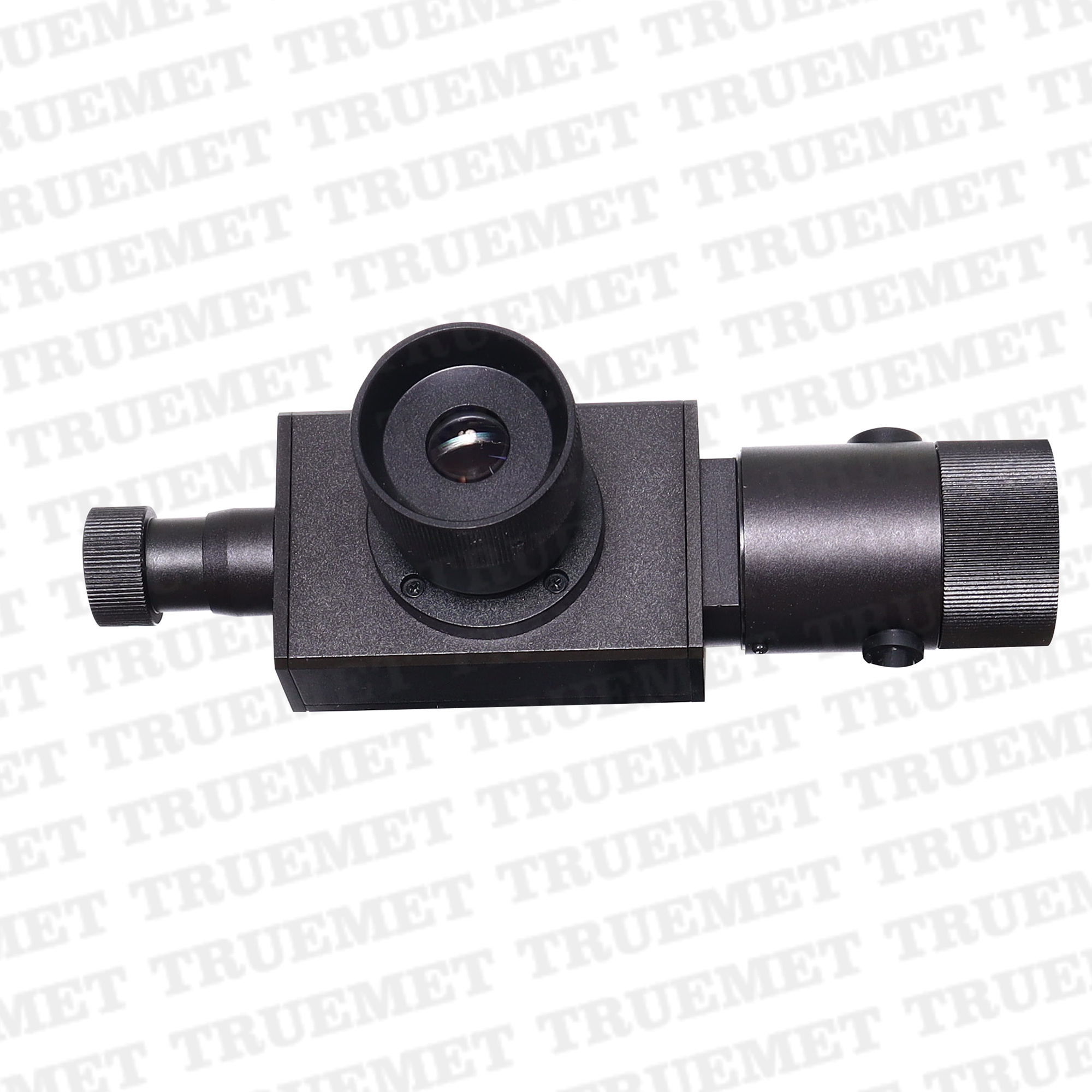

FeaturesMANUAL EYEPIECE :Equipped with 10x Manual Eyepiece to measure the length of diagonal. The hardness value can be displayed directly on LCD screen by entering the indentation diagonal length.

CAMERA PORT :Machine equipped with dual optical channel, one optical channel for 10X eyepiece and another optical channel is for camera by which machine can be upgraded into computerized / computer controlled model. Both optical channel works simultaneously.

ILLUMINATION SYSTEM :Halogen illumination unit with adjustable intensity gives very clear images and can be also used as a simple microscope. Halogen illumination unit enter stand by mode after a certain period of inactivity which gives it a long service life and low power consumption.

AUTO TURRET MECHANISM :Equipped with auto turret mechanism. Auto turret perform a series of operation and measuring lens automatically comes back to central position after making indentation. The position of the indenter and the objective lens can be automatically switched using touch panel.

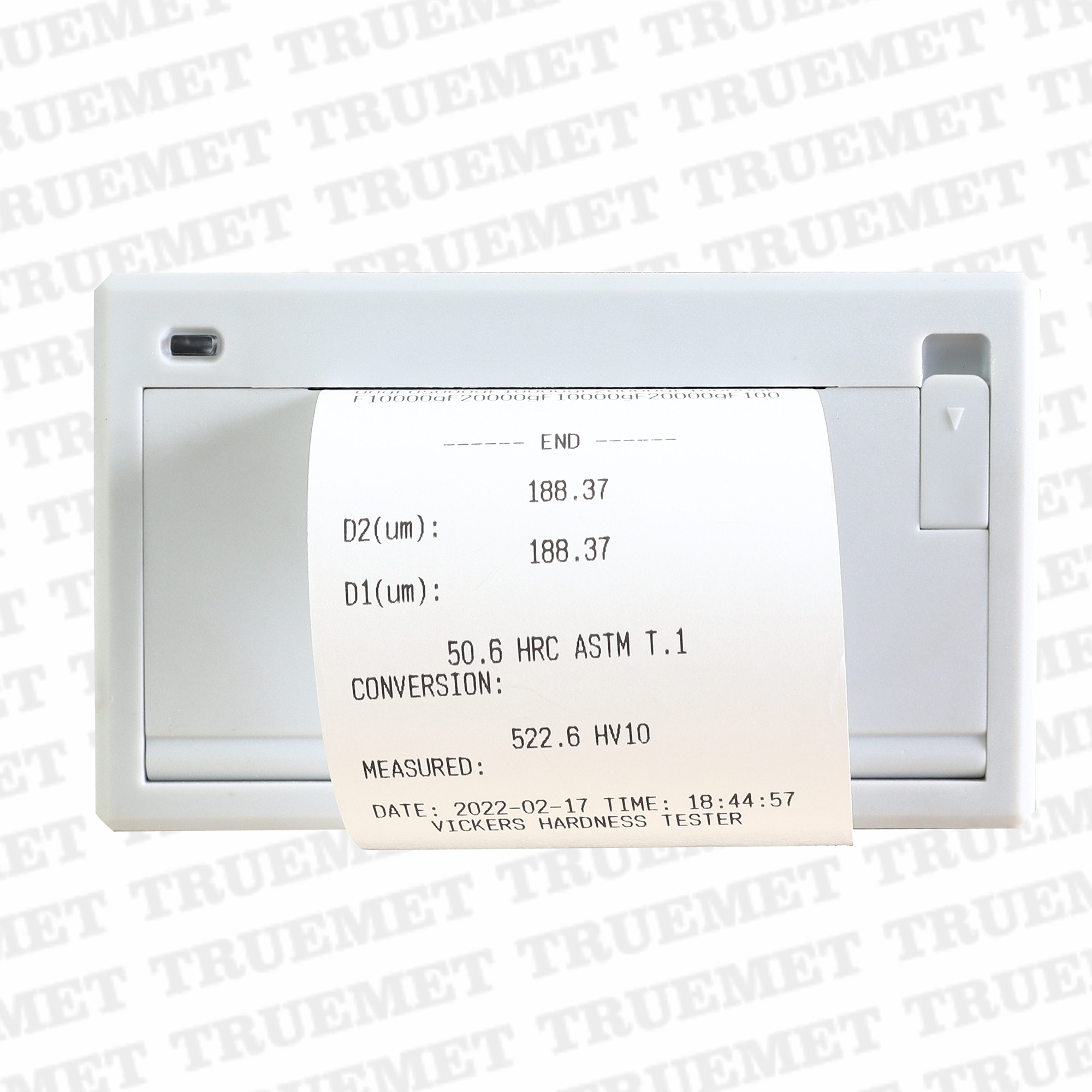

DATA OUTPUT :Equipped with built is thermal printer to take the print out the hardness result USB port is also available to get the data in pendrive.

TEST FORCE :Wide range of test force can be selected with external force selection knob. The test force is automatically displayed on the 7 inch LCD touch display.

LCD TOUCH SCREEN PANEL :7 Inch LCD touch screen can visually display the hardness value, conversion hardness, test force, dwell time, statistical data, upper & lower limit and brightness of optical system.

EMERGENCY SWITCH :Equipped with emergency stop switch.

Advanced Touch Screen Control and Automation

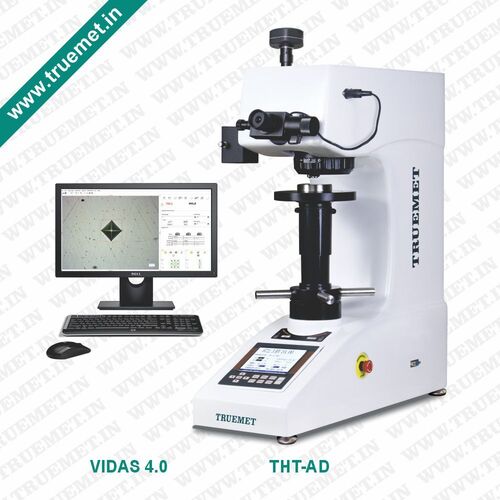

This tester boasts a responsive 7-inch color LCD touch screen for intuitive operation and quick configuration. With VIDAS 4.0 software, users experience seamless navigation and customizable testing protocols, ideal for routine labs or complex research environments. The automated, closed-loop load application, motorized turret, and X-Y stage ensure efficiency and minimize human error, while multiple control modes accommodate both manual and automatic preferences.

Precision and Versatility for Metallurgical Applications

With an accuracy of 1.0% and resolution down to 0.01 m, the VHT-AT Series delivers reliable micro and macro Vickers measurements. Its integrated high-resolution camera enables automatic image analysis, and variable LED illumination optimizes visibility. The automatic X-Y stage, a 135 mm test width, and capacity for specimens up to 130 mm thick make this an indispensable tool for testing various metals and alloys.

Comprehensive Data Management and Connectivity

Designed for modern laboratories, this tester supports data storage for up to 100,000 entries. Test results can be exported via USB, RS232, HDMI, or printed directly, facilitating straightforward documentation and traceability. Multilingual support broadens usability across diverse teams, and network export capabilities make sharing results effortless for quality control and compliance.

FAQs of Touch Screen Vickers Hardness Tester (VHT-AT Series with VIDAS 4.0):

Q: How does the motorized turret enhance the Vickers Hardness Testers usability?

A: The testers motorized 6-position turret automates the selection of objectives and indenters, enabling rapid switching between test configurations. This minimizes setup time, increases workflow efficiency, and ensures consistent measurements by reducing manual intervention.Q: What is the process for measuring hardness using the integrated camera and auto image analysis?

A: After positioning the specimen on the automatic X-Y stage, the tester applies the selected load and creates an indentation. The integrated high-resolution CCD camera captures the indentation, and VIDAS 4.0 automatically analyzes the image, providing precise measurement results quickly.Q: When is it necessary to use the automatic versus manual calibration method?

A: Automatic calibration is recommended for routine use, ensuring consistent accuracy with minimal effort. Manual calibration may be required for specialized testing, validation, or when using new or non-standardized specimens, allowing operators greater control over calibration parameters.Q: Where can data from the VHT-AT Series be exported for analysis or archiving?

A: Data can be exported via USB, printer port, RS232, or HDMI ports. It also supports network export, allowing results to be transferred to local servers, external storage, or laboratory information systems for documentation and further analysis.Q: What benefits does the automatic, closed-loop load control provide during testing?

A: Closed-loop control ensures that each load is applied precisely and consistently, which is vital for reproducible results. This automation enhances test reliability, reduces variability, and supports stricter compliance with international testing standards.Q: How do the high-capacity data storage and touchscreen interface improve laboratory workflow?

A: Storing up to 100,000 test entries allows long-term record-keeping without frequent data management. The 7-inch touch screen streamlines test setup, navigation, and data entry, increasing throughput and reducing training time for new users.Q: Which industries or applications particularly benefit from the VHT-AT Series Hardness Tester?

A: The tester is ideal for metallurgical laboratories, quality control departments, research facilities, and engineering workshops needing precise, automated Vickers hardness measurements on metals and alloys. Its versatility and detailed analytics support product development, process validation, and materials certification.

More Products in Vicker Hardness Tester Category

Load Cell Based Digital Vickers Hardness Tester (THT-AD Series)

Minimum Order Quantity : 1 Number

Power Supply : AC220V±5% 5060Hz

Machine Weight : 42 Kilograms (kg)

Test Range : 53000 HV (Vickers Hardness)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Capacity : 5 kgf, 10 kgf, 30 kgf selectable (as per model)

Computerized Digital Touch Screen Vickers Hardness Tester (VHT-DT Series with VIDAS 2.0)

Minimum Order Quantity : 1 Number

Power Supply : AC220V±5% 5060Hz

Machine Weight : 42 Kilograms (kg)

Test Range : 5g 3kgf (Vickers Load Range)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Capacity : Variable, as per standard model configuration

Computer Controlled Load Cell Based Digital Vickers Hardness Tester (THT-AD SERIES with VIDAS 4.0)

Minimum Order Quantity : 1 Millimeter

Power Supply : AC220V±5% 5060Hz

Machine Weight : 42 Kilograms (kg)

Test Range : 5g ~ 2kg (Load Cell based)

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Capacity : High repeatability and reliability

Computerized Load Cell Based Vickers Hardness Tester (THT-A Series with VIDAS 2.0)

Minimum Order Quantity : 1 Millimeter

Power Supply : AC220V±5% 5060Hz

Machine Weight : 42 Kilograms (kg)

Test Range : 1 HV ~ 3000 HV

Dimension (L*W*H) : 585X200X630 Millimeter (mm)

Capacity : Load 1gf to 1000gf

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry